Reading Time: Approximately 15 minutes

Labor costs rising by 4% annually. Staff turnover exceeding 70% at many operations. Food consistency becoming the differentiator between thriving chains and struggling independents. If you’re a culinary leader navigating these realities, you already know that conventional cooking equipment can’t solve modern operational challenges.

This buying guide cuts through the marketing noise to deliver actionable intelligence on Rational combi ovens—the automation infrastructure that’s helping commercial kitchens reduce labor dependency by 12-23%, standardize output across multiple sites, and reclaim valuable kitchen footprint. Whether you’re spec’ing equipment for a new build, replacing aging infrastructure, or scaling a multi-unit concept, you’ll learn exactly which Rational model fits your operation, how to calculate your true payback period, and how to avoid the three warranty mistakes that cost operators thousands in preventable repairs.

Key Takeaways

- Strategic Investment Framework: Rational combi ovens deliver measurable ROI through three proven channels—labor automation (15-23% reduction in prep hours), energy efficiency (18-30% lower consumption vs. traditional stacks), and waste mitigation (8-20% food cost savings via precision cooking).

- Model Selection Clarity: The iCombi Pro justifies its premium through four intelligent assistants that reduce staff training by 8+ hours and enable complex menu execution. The iCombi Classic offers 30% smaller footprint and 10% energy savings, ideal for standardized QSR applications where automation complexity isn’t required.

- Electrical Reality Check: Plan for dedicated circuits—a 10-pan iCombi Pro requires 18.9 kW (60A breaker at 208/240V), while 20-pan models demand 67.9 kW (200A). Underpowered installations throttle performance and void warranties.

- Maintenance = Warranty Protection: Monthly descaling (15 minutes) extends equipment lifespan by 3+ years. Using non-approved cleaning chemicals voids steam generator coverage—the costliest repair at $900-$1,200.

- Competitive Positioning: Rational’s 12-minute interim cleaning beats Unox’s 22-minute cycle, and its North American service network offers 40% more certified technicians for faster repair response.

Why Combi Ovens Are Critical for Modern Kitchens (Beyond Fad Status)

The commercial kitchen landscape has fundamentally shifted. What worked in 2019—relying on experienced line cooks, tolerating 15% food waste, and stacking single-function equipment—no longer pencils out when labor costs $14.92/hour on average and 70% of operators report unfillable positions.

Combi ovens aren’t trendy gadgets; they’re strategic responses to structural industry challenges. Here’s the data that matters.

Labor Cost Inflation: How Combi Ovens Offset Rising Wages

Foodservice wages increased 4% year-over-year in 2024, outpacing overall inflation at 2.6%. For a 50-seat restaurant running two cooks per shift, that’s an additional $8,300 in annual payroll just to maintain current staffing levels. Meanwhile, 45% of operators report they lack enough employees to meet customer demand.

Rational’s automation directly addresses this gap. The iCookingSuite’s intelligent cooking paths eliminate the constant monitoring traditional equipment demands. Instead of a cook checking oven temps every 8 minutes, adjusting vents, and rotating pans, the iDensityControl system measures humidity 3,600 times per hour and self-corrects. This freed capacity translates to measurable labor savings.

Real-world impact: A 200-cover restaurant deploying two iCombi Classic units documented 35 fewer labor hours monthly—equivalent to $455 in savings at £13/hour ($17 USD), or $5,460 annually. Scale that to a four-unit chain and you’re offsetting 0.75 full-time equivalents across the organization.

Consistency Matters: Reducing Variance Across Locations

Multi-unit operators face an invisible profitability killer: recipe drift. When each location interprets “golden brown chicken” differently, you’re managing variable food costs, inconsistent customer experiences, and higher rework waste.

Rational’s programmable cooking paths eliminate this variance. The iCookingSuite stores up to 1,200 recipes with 12-step sequences. Upload a program via ConnectedCooking’s cloud platform, and your Nashville location cooks the same honey-glazed salmon as your Denver site—same browning, same internal temp, same moisture retention.

Industry estimates suggest this standardization reduces plating variance by 45-60% in multi-unit deployments. One four-unit restaurant group documented 18% lower rework waste after implementing Rational ovens, directly improving food cost percentage—often a 2-3 point swing that drops straight to EBITDA.

Regulatory Tailwinds: Automated Logs Meet NSF/UL Compliance

Health inspectors increasingly demand documented proof of time-temperature compliance. Manual logs are error-prone and difficult to audit. Rational’s ConnectedCooking platform auto-generates HACCP-compliant records, logging cook times, core temperatures, and cleaning cycles.

This matters during inspections and in liability scenarios. NSF/ANSI 4-2024 standards require that commercial cooking equipment enables proper sanitation and prevents contamination. Rational’s iCareSystem identifies exact cleaning needs (eco vs. standard cycle) and logs completion—creating an auditable trail that satisfies both health departments and insurance underwriters.

Space vs. Capacity: One Combi Oven Replaces 3-4 Traditional Appliances

Urban real estate costs $35-$85/sq ft annually in major metro markets. Every piece of equipment must justify its footprint. A traditional cooking line—convection oven, steamer, proofer, and holding cabinet—consumes 35-40 sq ft. A single Rational iCombi Classic occupies less than 9 sq ft (approximately 1 m²) while delivering all four functions.

For QSR operators targeting ghost kitchen formats or retrofitting existing spaces, this consolidation is non-negotiable. The iCombi Classic 10-pan fits under standard ventilation at 42″ height when double-stacked, enabling 20-pan total capacity in the same vertical footprint competitors require for 10 pans.

Key Buying Criteria: Matching Rational Models to Your Operation

Equipment specs matter less than operational fit. Before evaluating pan capacity or power requirements, answer three strategic questions: What’s your daily volume? How much menu variance do you carry? What’s your staff’s technical skill level?

Daily Covers Guide: What Size Do You Actually Need?

Rational offers six capacity tiers. Here’s the decision framework based on actual throughput data:

50-100 covers/day: iCombi Classic 6-pan (6 half-size sheet pans or 12 full-size hotel pans). Ideal for fast-casual concepts, small cafes, or food trucks with limited menu rotation. Footprint: 33.5″ W × 29.6″ H × 30.5″ D.

100-200 covers/day: iCombi Classic 10-pan. Handles breakfast through dinner service in a 75-seat restaurant. Double-stack configuration (two 10-pan units) provides 20-pan capacity without expanding horizontal footprint—critical for inline shopping center spaces with tight kitchen dimensions.

200-400 covers/day: iCombi Pro 10-pan. The automation jump (iProductionManager, iDensityControl) justifies the 15-20% cost premium when menu complexity increases. A hotel restaurant running breakfast buffets, à la carte lunch, and banquet prep simultaneously needs the Pro’s task-sequencing intelligence.

400-800 covers/day: iCombi Pro 20-pan (20 full-size sheet pans or 40 hotel pans). Large full-service restaurants, hotel banqueting, and institutional kitchens. Dimensions: 43.5″ W × 74.9″ H × 36.4″ D. Weight: 717 lb—requires reinforced flooring in some installations.

800+ covers/day: Double-stack iCombi Pro 20-pan configuration. Convention centers and high-volume caterers. Total capacity: 40 full-size pans. Combined power draw: 135.8 kW—verify electrical service capacity before specifying.

Electrical Infrastructure: Avoiding Costly Surprises

Combi ovens are power-intensive. Underestimate electrical requirements and you’ll face $8,000-$15,000 in panel upgrades and conduit runs—costs that destroy ROI projections.

iCombi Classic 6-pan (electric): 10.8 kW, 60A breaker, 3-phase 208/240V. Cable: AWG 14.

iCombi Pro 10-pan (electric): 18.9 kW, 60A breaker at 208/240V or 30A at 440/480V. Cable: AWG 4 (208/240V) or AWG 8 (480V).

iCombi Pro 20-pan (electric): 67.9 kW, 200A breaker at 208/240V. Cable: AWG 3/0. Running amps: 188.5A at 208V, 163.3A at 240V. This requires dedicated service—you cannot share circuits with other equipment.

Gas considerations: Natural gas models reduce electrical load but require 3/4″ NPT gas lines with shut-off valves. A 10-pan gas unit draws 83,500 BTU total (82,000 BTU steam mode). Verify gas pressure: 6.5-10″ w.c. for 6-pan models, 10-15″ w.c. for larger units.

Critical spec: All Rational units require 3-phase power. Single-phase service necessitates a phase converter ($2,500-$6,000 installed), adding to total project cost.

Footprint Math: iCombi Classic vs. Pro Space Efficiency

When real estate costs $50/sq ft annually, equipment footprint directly impacts profitability. The iCombi Classic’s smaller total dimensions (body + clearances) deliver measurable savings:

- iCombi Classic 10-pan: 33.5″ W × 39.9″ H × 30.5″ D (body dimensions). Total footprint with service clearances: ~18.5 sq ft.

- iCombi Pro 10-pan: Identical body dimensions but requires additional clearance for the 10.1″ touchscreen and service access. Total footprint: ~22 sq ft.

For QSR chains deploying standardized 1,200 sq ft formats, that 3.5 sq ft difference accommodates an additional reach-in refrigerator or prep table—equipment that directly supports throughput.

Steam vs. Convection: Menu Flexibility Examples

Rational units operate in three primary modes: steam (212°F saturated), convection (up to 572°F dry heat), and combi (simultaneous steam + convection). Understanding which modes your menu demands prevents overbuying automation you won’t use.

Steam-intensive applications: Vegetables, seafood, Asian dumplings, rice, proofing bread. The high-performance steam generator produces optimal saturation even at low temps below 212°F. Restaurants featuring steamed whole fish or dim sum service require robust steam capacity—a core strength of Rational’s boiler-based system (vs. Unox’s direct steam injection).

Convection-intensive applications: Roasted meats, baked goods, pizza (when using oven-safe stones), finishing au gratin dishes. Dry convection at 450-500°F develops Maillard browning.

Combi-mode applications: This is where Rational excels. Simultaneous steam + convection allows slow-roasted pork shoulder (moisture retention) with crispy bark (surface browning), or croissants with flaky layers and golden exteriors. The iDensityControl system adjusts humidity percentage in real-time, maintaining optimal cabinet climate even when doors open frequently during service.

Practical menu test: If 60%+ of your volume requires only convection (e.g., pizza-focused concepts, bakeries), a high-performance convection oven may be more cost-effective than a combi. Reserve combi investment for operations requiring true mode flexibility.

Rational Model Showdown: iCombi Pro vs. iCombi Classic

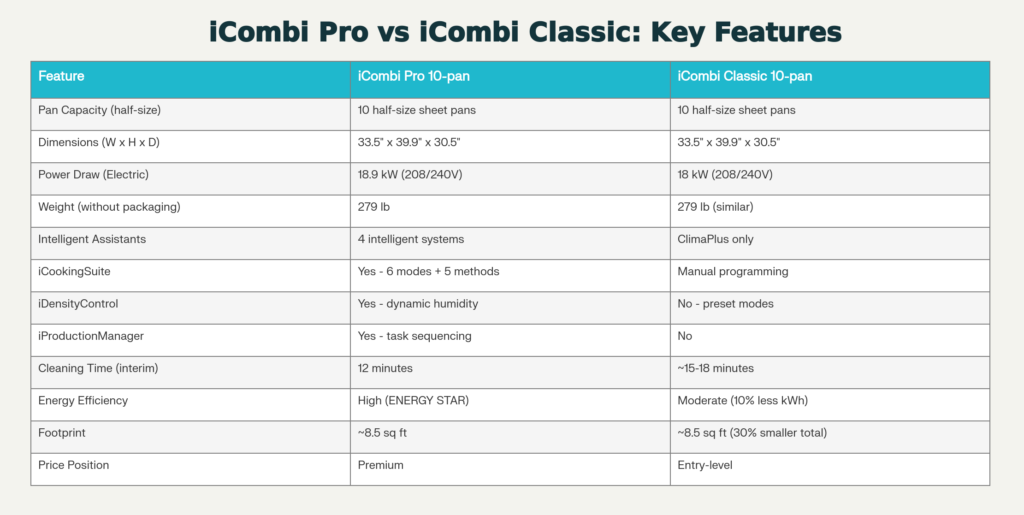

Feature-by-feature comparison of Rational’s iCombi Pro and iCombi Classic models shows the Pro’s advanced automation capabilities justify its premium positioning for high-variance menus

Rational positions two distinct product lines. The decision isn’t “which is better”—it’s “which solves my specific operational challenge.”

iCombi Pro: Automation for High-Variance Menus

The iCombi Pro targets operations where menu complexity, staff turnover, or multi-site consistency justify premium automation.

Four Intelligent Assistants:

- iCookingSuite: The core cooking intelligence. Select from 6 operating modes (steam, combi-steam, convection, etc.) and 5 cooking methods (roasting, baking, poaching, etc.). Specify your desired end result (e.g., “medium-rare ribeye, caramelized crust”), and the system auto-adjusts cook time, temperature, and humidity. This guided cooking reduces new-hire training from 16 hours to 8 hours—documented by operators deploying Pro units in high-turnover environments.

- iDensityControl: Intelligent climate management measuring humidity 3,600 times/hour. The system combines sensors, active dehumidification, and flow-optimized cabinet geometry to create optimal cooking conditions. Real-world impact: 10% faster cooking times (reducing ticket times during peak service) and improved yield on expensive proteins through precise moisture control.

- iProductionManager: Task sequencing for batch cooking. The system organizes multi-item production orders, determining which dishes cook together on separate racks without flavor transfer, and staggers completion times for plating coordination. A hotel preparing a 200-guest banquet—appetizers at 7:00 PM, entrées at 7:45 PM, desserts at 9:00 PM—relies on this scheduling intelligence to execute flawlessly with minimal supervision.

- iCareSystem: Self-diagnosing cleaning. The oven evaluates soiling level and recommends eco (12-minute) or standard (30-minute) cleaning cycles. Automatic descaling eliminates manual calcium removal—the #1 cause of steam generator failure. Over 5 years, this prevents $3,000-$5,000 in avoidable repairs.

Best-fit operations: Hotels with banqueting, full-service restaurants running 80+ menu items, multi-unit chains standardizing recipes across 4+ locations, institutional kitchens (universities, hospitals) where staff skill levels vary widely.

Cost justification example: A 150-seat restaurant deploying one iCombi Pro 10-pan ($48,000 investment) documents $31,440 annual savings (labor + energy + waste). Payback: 14 months. The automation eliminates the need for one part-time prep cook ($18,000/year) while reducing rework waste by 15% ($6,500/year on a $325,000 annual food cost base).

iCombi Classic: Space Efficiency and Value

The iCombi Classic strips away advanced automation, delivering core combi functionality at an entry-level price point.

What you keep: Steam, convection, and combi modes. ClimaPlus active climate management (though not the Pro’s real-time humidity sensing). Manual recipe programming with multi-step sequences. Self-cleaning with iCareSystem (standard cycle only, no eco-mode).

What you lose: iCookingSuite’s guided cooking (you manually set temp/time/humidity). iDensityControl’s adaptive adjustments. iProductionManager’s task sequencing. The 10.1″ touchscreen (Classic uses a smaller 4.3″ display).

Measurable advantages:

- Footprint: 30% smaller total installation requirements vs. Pro (manufacturer claim; validated by 42″ double-stack height fitting under standard Type I hoods).

- Energy efficiency: 10% lower kWh consumption due to simpler controls and smaller heating elements. For a 5,000-hour annual runtime, that’s 900 kWh saved, or ~$110/year at $0.12/kWh.

- Purchase price: Typically 20-25% less than equivalent Pro capacity.

Best-fit operations: Fast-casual chains with standardized menus (5-12 core items), QSR breakfast programs, ghost kitchens focusing on delivery/takeout, small independent restaurants where the owner-operator has culinary expertise and doesn’t need guided cooking prompts.

Cost justification example: A QSR running 100 covers/day invests $32,000 in an iCombi Classic 6-pan. Annual savings: $22,400 (labor, energy, waste reduction). Payback: 17 months. The simpler interface matches staff skill levels—counter workers operate the Classic with minimal training, whereas the Pro’s advanced features would go underutilized.

When to Upgrade: Decision Framework

Choose iCombi Pro if:

- Menu exceeds 30 items with frequent seasonal rotations

- Staff turnover exceeds 50% annually (high training burden)

- Operating 2+ locations requiring recipe standardization

- Banqueting/catering represents 25%+ of revenue

- You lack a skilled sous chef or kitchen manager onsite daily

Choose iCombi Classic if:

- Menu consists of 5-15 high-volume items

- Ownership/management has strong culinary background

- Operating a single location with stable staff

- Purchase budget is constrained ($30K-$40K vs. $45K-$65K)

- Kitchen space is extremely limited (Classic’s smaller footprint matters)

Rational vs. Unox: Automation, Reliability & Service Face-Off

Equipment decisions shouldn’t rely on brand loyalty—they require objective performance comparisons. Unox positions itself as the value alternative to Rational. Here’s where the substantive differences emerge.

Automation Comparison: Precision vs. Complexity

Rational’s sensor-driven adjustments: The iDensityControl system continuously measures actual humidity and auto-corrects mid-cycle. If cooks leave the door open 30 seconds longer than programmed (common during peak service), the system detects the temperature drop and extends cook time 2-3 minutes to compensate. This adaptive intelligence prevents undercooked proteins and overcooked vegetables when real-world conditions deviate from ideal scenarios.

Unox’s preset approach: Unox ovens use pre-programmed humidity levels without real-time sensing (on non-premium models). Operators set “60% humidity” and the oven maintains that target, but it can’t detect when door openings or colder-than-expected product loads require adjustment. Experienced cooks compensate manually; less-skilled staff produce inconsistent results. Reddit

Training burden: Rational’s guided cooking interface (iCookingSuite) reduces onboarding time by approximately 8 hours vs. Unox’s manual programming. For operators running 30%+ annual turnover, that’s 2.4 hours saved per new hire—meaningful when training interrupts service flow.

Cleaning Efficiency: Time is Money

Interim cleaning comparison:

- Rational iCareSystem: 12 minutes for eco-clean cycle.

- Unox standard cleaning: 22 minutes (per user forum reports).

In a high-volume kitchen running 3 services daily, that 10-minute difference compounds. Annual time saved: 182 hours, or $2,366 at $13/hour labor cost. Additionally, Rational’s phosphate-free cleaner tabs reduce chemical costs by 50%.

Descaling automation: Rational’s automatic descaling extends steam generator lifespan by 3+ years. Unox requires more frequent manual descaling in hard-water regions—a maintenance task often deferred until performance degrades, leading to costly generator replacements ($1,200 vs. $900 for Rational).

Long-Term Costs: Proprietary Parts & Downtime

Service network density: Rational operates the largest North American service network for combi ovens, with factory-certified technicians in 40% more markets than Unox. This matters during equipment failures—a 48-hour repair delay in a single-oven operation can cost $3,000-$8,000 in lost revenue and disappointed customers.

Parts availability: Rational’s market dominance (estimated 60%+ share in premium segment) means parts stock faster. Independent service techs report Unox steam generators backorder 7-10 days vs. 2-3 days for Rational equivalents.

Warranty considerations: Both brands offer standard 2-year parts and labor coverage. However, Rational’s warranty explicitly requires using approved cleaning chemicals (NSF-certified products only). Using generic degreasers voids steam generator coverage—the costliest repair. Unox enforces similar requirements but with less rigorous documentation, creating ambiguity during warranty claims.

Price Reality Check

Unox typically prices 15-20% below equivalent Rational capacity. For a 10-pan combi oven:

- Rational iCombi Classic: ~$38,000-$42,000

- Rational iCombi Pro: ~$48,000-$54,000

- Unox ChefTop: ~$32,000-$36,000

That $6,000-$12,000 savings matters for budget-constrained operators. But factor in:

- Higher training costs (less automation)

- Longer cleaning cycles (labor expense)

- Potentially slower service response (smaller network)

- Resale value (Rational holds 60-70% of purchase price after 5 years vs. 45-55% for Unox)

Decision framework: Unox makes sense for single-location operators with strong culinary leadership who can manually optimize cooking programs and don’t require guided automation. Rational justifies its premium for multi-unit chains, high-turnover operations, and kitchens where consistency cannot depend on individual skill level.

Investment payback periods for Rational combi ovens vary by operation size, with mid-to-large volume kitchens seeing faster returns through labor automation and waste reduction

Combi Oven ROI: Calculating Your Payback Period

Equipment ROI isn’t theoretical—it’s quantifiable across three categories: labor savings, energy efficiency, and waste reduction. Here’s the framework to calculate your specific payback.

Labor Math: Quantifying Automation Value

Combi ovens reduce labor through:

- Elimination of constant monitoring (automated climate control)

- Simplified cleaning (12-minute interim cycle vs. 45 minutes manual scrubbing of multiple appliances)

- Reduced training time (guided cooking interfaces)

- Batch production efficiency (cook 10 items simultaneously vs. sequential cooking)

Calculation approach:

Baseline your current labor hours dedicated to cooking/cleaning. A typical 200-cover restaurant allocates:

- 4 hours daily for oven-related cooking tasks (monitoring, rotating, adjusting)

- 1.5 hours daily for cleaning traditional equipment (convection oven, steamer, grill surfaces)

- 8 hours training new hires on equipment operation

Post-combi labor requirement:

- 2.5 hours daily for cooking (automation reduces monitoring by 60-70%)

- 0.3 hours daily for cleaning (iCareSystem automated cycles)

- 4 hours training (simplified interface)

Annual savings calculation:

- Daily labor saved: 3.2 hours × 360 operating days = 1,152 hours

- Labor cost: 1,152 hours × $17/hour (average foodservice wage) = $19,584

- Training savings: 4 hours × 8 new hires/year × $17/hour = $544

- Total labor savings: $20,128/year

This aligns with Rational’s documented case studies showing 35 fewer labor hours monthly, or $5,460 annually.

Energy Efficiency: kWh and BTU Savings

ENERGY STAR-certified combi ovens (including Rational Pro models) achieve 20-30% greater efficiency than standard convection ovens. The savings stem from:

- Shorter pre-heat times (4 minutes to 212°F vs. 15-20 minutes for traditional equipment)

- Combined functionality (one unit replaces 3-4 appliances)

- Optimized idle energy rates (1.4 kW max for full-size electric models)

Calculation approach:

A traditional cooking line—convection oven, steamer, and holding cabinet—consumes approximately:

- Convection oven: 6,300 kWh/year

- Steamer: 4,800 kWh/year

- Holding cabinet: 2,100 kWh/year

- Total: 13,200 kWh/year

An iCombi Classic 10-pan consuming 1,890 kWh/year replaces all three.

Energy savings:

- Reduction: 11,310 kWh/year

- At $0.12/kWh average commercial rate: $1,357/year

For gas models, ENERGY STAR-certified combi ovens save approximately 340 MMBtu annually, or $5,300. These savings are substantial for high-volume operations running ovens 12+ hours daily.

Waste Reduction: Precision Cooking’s Financial Impact

Rational’s moisture control and temperature precision reduce three types of waste:

1. Protein shrinkage: Proper steam injection during roasting reduces meat/fish shrinkage by up to 25%. For a restaurant purchasing $8,000/month in proteins, that’s $24,000 annual cost-of-goods improvement.

2. Overcooking/rework: Consistent results eliminate re-fires. A 200-cover restaurant experiencing 12 re-fires weekly (6% error rate) wastes $312/week at $26 average plate cost, or $16,224/year. Reducing errors to 2% saves $10,816.

3. Fat usage: Combi cooking nearly eliminates added fats. Savings of 95% on fat purchasing and disposal—typically $500-$800/year for mid-sized operations.

Conservative waste savings estimate: $12,000-$18,000 annually for a 200-cover restaurant.

Input Variables: What to Track Before Buying

Accurate ROI projections require baseline data:

- Current energy bills: 12 months of utility statements showing kWh usage and peak demand charges

- Labor schedules: Total hours dedicated to cooking and cleaning equipment

- Food waste logs: Track rework incidents, over-portioning, and shrinkage percentages

- Training time: Hours spent onboarding new kitchen staff

- Menu complexity: Number of SKUs and cooking methods required

Without this data, you’re guessing. Operators who meticulously track these metrics achieve payback 20-30% faster than those using generalized industry averages.

5-Year NPV Scenarios

Scenario 1: QSR (100 covers/day)

- Investment: $32,000 (iCombi Classic 6-pan)

- Annual savings: $22,400 (labor + energy + waste)

- 5-year total savings: $112,000

- Net present value (at 8% discount rate): $57,400

- Payback period: 17 months

Scenario 2: Mid-size restaurant (200 covers/day)

- Investment: $48,000 (iCombi Pro 10-pan)

- Annual savings: $40,540

- 5-year total savings: $202,700

- NPV: $114,100

- Payback period: 14 months

Scenario 3: Hotel/banquet (500+ covers/day)

- Investment: $62,000 (iCombi Pro 20-pan)

- Annual savings: $67,300

- 5-year total savings: $336,500

- NPV: $206,700

- Payback period: 11 months

These projections assume 5% annual inflation in labor/energy costs (conservative given recent trends) and stable equipment performance over the analysis period.

Maintenance & Compliance: Protecting Your Rational Investment

Purchase price is the beginning of total cost of ownership. Proper maintenance extends equipment lifespan from 8-10 years (industry average) to 12-15 years while preserving warranty coverage and preventing costly emergency repairs.

Descaling: The 15-Minute Task That Saves Thousands

Hard water deposits calcium carbonate on steam generator heating elements, reducing efficiency and eventually causing failure. Replacement cost: $900-$1,200 plus 2-3 days downtime.

Rational’s descaling protocol:

- Frequency: Monthly in hard-water regions (150+ ppm calcium), quarterly in soft-water areas.

- Process: iCareSystem auto-detects scale buildup and prompts descaling. The 15-minute cycle uses citric acid to dissolve deposits.

- Preventive impact: Extends steam generator lifespan by 3+ years, saving $900-$1,200 in replacement costs plus $3,000-$5,000 in lost revenue during repairs.

Critical requirement: Use only Rational-approved descaling agents. Generic products (even those marketed as “combi oven compatible”) may void warranty if chemical analysis traces equipment damage to non-approved substances.

NSF Must-Dos: Log Cleaning Cycles + Use Approved Chemicals

NSF/ANSI 4-2024 establishes sanitation standards for commercial cooking equipment. Compliance isn’t optional—health inspectors cite violations that can trigger permit suspensions.

NSF cleaning requirements:

- Food contact surfaces: Must be cleanable to a microbiologically safe level. Rational’s seamless stainless steel cooking chamber with rounded corners meets this standard, but only if properly cleaned.

- Documentation: Health departments increasingly demand proof of cleaning frequency. ConnectedCooking’s cloud platform auto-logs every iCareSystem cycle (date, time, cycle type, duration)—creating HACCP-compliant records.

- Approved chemicals: Use NSF-certified cleaning products only (Category A1, A8, or D1). Rational’s phosphate-free cleaner tabs are NSF-listed and specifically formulated for stainless steel + steam generator compatibility. Laser Chemicals

Warranty protection: Rational’s terms explicitly state that damage caused by unauthorized chemicals voids coverage—even if the chemical is NSF-certified for other equipment types. This protects Rational from liability but shifts risk to operators who cut corners on cleaning supplies to save $50/month.

Warranty Pitfalls: Avoid These 3 Common Mistakes

Mistake #1: Using off-brand cleaning chemicals

Operators attracted to 30% cheaper generic descalers face warranty denial when steam generators fail. Rational’s service techs perform chemical residue analysis on warranty claims—detecting non-approved substances voids coverage. Replacement cost: $900-$1,200 out-of-pocket.

Mistake #2: Deferred maintenance

Skipping monthly descaling because “the oven still works fine” allows scale buildup to progress from minor (reversible with cleaning) to severe (requires element replacement). By the time performance degrades noticeably, damage is permanent.

Mistake #3: Non-certified repairs

Using a generic appliance repair service (rather than factory-certified technicians) to save on service call fees ($150 vs. $95) voids warranty if subsequent failures trace to improper repair procedures. Rational requires all warranty work be performed by authorized service providers.

Cleaning Protocols for High-Volume Kitchens

Interim cleaning (12 minutes): Run after each service period when oven is lightly soiled. Uses minimal water and chemicals—ideal for operations running 3+ services daily.

Standard cleaning (30 minutes): Full descaling cycle. Run weekly or when iCareSystem prompts heavier soiling.

Overnight cleaning: Schedule during closed hours to avoid production interruption. Rational ovens run unsupervised overnight cleaning cycles with automatic shut-off.

Multi-unit tip: Wi-Fi-enabled models (standard on iCombi Pro) connect to ConnectedCooking for remote diagnostics. Corporate operations managers monitor cleaning compliance across 10-15 locations from a single dashboard, flagging sites with overdue maintenance before equipment failures occur.

Getting Started: Next Steps for Culinary Leaders

Equipment decisions involve multiple stakeholders—culinary directors, facilities managers, CFOs. Here’s your pre-purchase validation framework.

Pre-Purchase Checklist: Validate These 5 Items

1. Electrical capacity audit

Hire a licensed electrician to verify:

- Available amperage on main panel (combi ovens require dedicated circuits)

- 3-phase service availability (single-phase requires costly converter)

- Conduit paths from panel to proposed equipment location

- Estimated installation cost ($3,000-$8,000 for new circuits)

2. Space mockup

Use cardboard templates (match exact equipment dimensions) to verify:

- Door swing clearance (Rational doors open 180°—need 36″ clearance)

- Service access (20″ recommended on left side for technician access)

- Ventilation compatibility (gas models require Type I hood; electric models often exempt)

- Loading height (can staff safely load upper racks on double-stack configurations?)

3. Labor baseline

Document current state:

- Hours spent monitoring cooking equipment daily

- Cleaning time for traditional ovens/steamers

- Training hours for new hires

- Re-fire frequency and rework waste

This data validates ROI projections and provides post-installation benchmarks.

4. Menu analysis

List all menu items requiring oven/steamer/combi capacity. Identify:

- Peak production windows (breakfast rush, dinner service)

- Simultaneous cooking requirements (how many items cook at once?)

- Temperature range needed (low-temp sous vide to high-temp roasting?)

- Steam intensity requirements

Avoid overbuying capacity. A 6-pan unit handling 80% of current volume at 90% utilization is better investment than a 10-pan unit at 60% utilization.

5. Water quality test

Obtain water hardness report from local utility or test independently. Hard water (150+ ppm calcium) requires:

- Monthly descaling (vs. quarterly for soft water)

- Possible water softener installation ($1,500-$3,500)

- Higher maintenance costs over equipment lifespan

Vendor Red Flags: What to Avoid

Red flag #1: No local service

Verify that authorized Rational service providers operate within 50 miles. Longer distances mean higher travel charges ($150-$300) and slower response times.

Red flag #2: Hidden parts fees

Some dealers markup parts 40-60% above Rational’s list prices. Request parts pricing disclosure upfront—especially for consumables like cleaning tabs and water filtration.

Red flag #3: Generic financing

Equipment financing through third-party lenders often carries 12-18% APR. Rational’s direct financing programs (through participating dealers) offer 6-9% rates for qualified buyers with better terms.

Red flag #4: Inadequate training

Standard delivery includes equipment drop-off and basic startup. Demand comprehensive training:

- Minimum 4-hour onsite session with kitchen staff

- Demonstration of all cooking modes

- Cleaning and descaling walkthroughs

- Troubleshooting common issues

Rational offers no-charge 4-hour certified chef assistance programs—verify your dealer includes this.

Demo Questions: What to Test During Trials

Most dealers offer trial periods (7-14 days). Use this window strategically:

Test #1: Staff usability

Can your least-experienced cook operate the unit with minimal guidance? If the iCookingSuite interface confuses current staff, the Pro’s automation won’t deliver promised training savings.

Test #2: Menu validation

Cook your five highest-volume items. Evaluate:

- Consistency across multiple batches

- Cooking times vs. current equipment

- Yield improvements (weigh proteins before/after cooking)

- Organoleptic quality (taste, texture, appearance)

Test #3: Cleaning reality check

Run the interim cleaning cycle after lunch service. Does 12 minutes actually clean adequately, or does residual buildup require manual scrubbing? This validates ongoing labor savings claims.

Test #4: Integration workflow

How does the combi oven fit your production flow? Does it create bottlenecks (all items funnel through one unit) or enable parallelization (cook multiple components simultaneously)?

SAH Kitchen Equipment Value-Add: Why Operator-Focused Dealers Matter

Purchasing from operator-focused dealers (vs. big-box distributors) provides:

Onsite demos: Test equipment in your kitchen with your menu before committing. Validate electrical compatibility, workflow integration, and staff adoption.

Financing options: Access manufacturer-backed programs with competitive rates. Preserve capital for other operational needs.

24-hour support: When equipment fails at 6 PM on Friday before a 200-guest banquet Saturday, you need immediate response. Operator-focused dealers maintain emergency service networks.

Post-installation training: Beyond standard 4-hour sessions, ongoing support helps staff master advanced features (recipe programming, Connected Cooking integration, production scheduling).

Some Useful Resources

Manufacturer Resources:

- Rational iCombi Pro Official Specifications – Detailed technical data sheets for all Pro models

- Rational iCombi Classic Product Information – Classic model specifications and features

- Rational ROI Calculator – Interactive tool for calculating equipment payback

Industry Standards & Compliance:

- NSF/ANSI 4-2024: Commercial Cooking Equipment Standards – Official sanitation and safety requirements

- ENERGY STAR Commercial Ovens Program – Efficiency specifications and certified models list

Market Intelligence:

- 2024 Restaurant Labor Market Insights – Current hiring challenges and wage inflation data

- Commercial Combi Ovens Market Analysis 2025-2030 – Industry growth trends and adoption rates

SAH Kitchen Equipment Resources:

- Commercial Kitchen Equipment TCO Calculator

- Cloud Kitchen Multi-Brand Throughput Calculator

- Commercial Kitchen Order Staging & Hot-Holding Planner

- Commercial Kitchen Peak Order Wave Analyzer

- Want the complete 72-point checklist covering every validation step, specification template, and vendor evaluation scorecard? Get your Commercial Kitchen Equipment Procurement Checklist for the comprehensive planning tools that prevent the $10,000+ mistakes we’ve documented in under-planned equipment projects.

Must Also Read

- Commercial Kitchen Equipment Buying Guide: Avoid Costly Mistakes & Maximize ROI (2025-2026 Updated)

- Bizerba Commercial Scales Buying Guide: Choose the Right Model for Compliance & Efficiency

- Commercial Steam Kettle Buying Guide: ROI-Focused Selection for High-Volume Kitchens

- Essential Cloud Kitchen Equipment: Maximizing Output in Under 500 Sq Ft (2025-2026 Guide)