Reading Time: Approximately 15 minutes

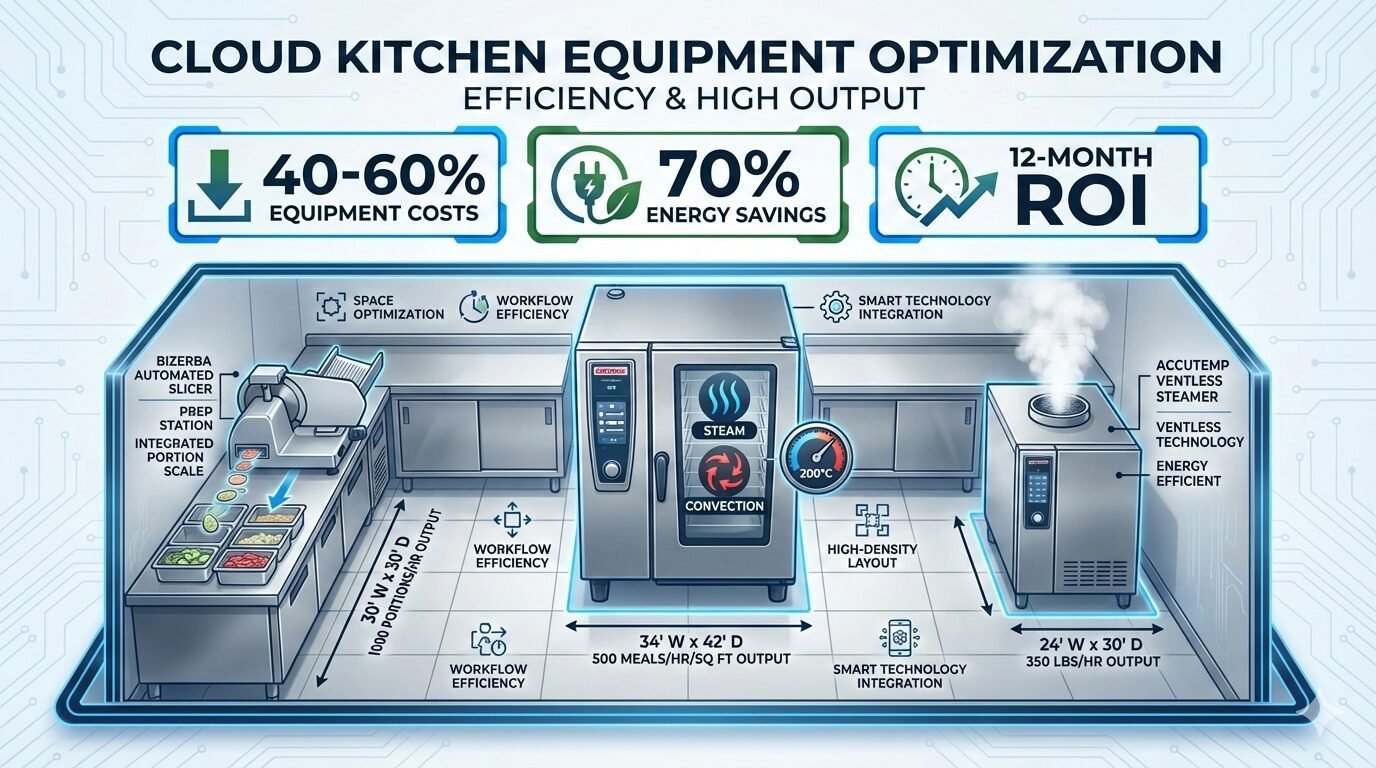

The US ghost kitchen market is poised to reach $88.42 billion in 2025, growing to $196.69 billion by 2032—a 12.1% compound annual growth rate driven by delivery-first consumer behavior and the collapse of traditional dine-in economics. But here’s the challenge that determines whether you succeed or become another failed concept: 40–60% of your startup capital gets locked into equipment decisions made inside spaces often smaller than a two-car garage.

If you’re managing a multi-brand cloud kitchen, launching a delivery-only concept, or converting underutilized restaurant space into a ghost kitchen hub, this guide addresses your core constraint—maximizing kitchen output per square foot while controlling upfront costs and ongoing utility expenses. You’ll discover how ventless equipment cuts $20,000+ in HVAC installation costs, why multifunctional gear like combi ovens can replace three separate appliances, and which equipment investments deliver payback in under 12 months.

This isn’t theory. It’s operational math grounded in real cloud kitchen economics, manufacturer specifications, and the regulatory frameworks that govern US ventless exemptions in over 20 major cities.

Key Takeaways

- Equipment consumes 40–60% of cloud kitchen startup budgets: Ventless technology can eliminate $40,000–$50,000 in HVAC installation costs, shifting capital toward revenue-generating operations.

- Combi ovens replace 3–4 traditional appliances in under 1 square meter of footprint: The Rational iCombi Pro operates in less than 11 square feet of space while handling 150–300 meals/day with 60–70% less energy consumption.

- Ventless exemptions are legally available in 20+ US cities: California, New York, and Seattle allow low-heat appliances (electric steamers, convection ovens) to operate without hoods when they meet UL 197 or UL 710 standards and NFPA 96 criteria.

- AccuTemp boilerless steamers use <1 gallon water/hour vs. 20–60 gallons for conventional steamers: This 95% water reduction cuts both consumption costs and HVAC cooling loads.

- Bizerba automated slicers achieve 120 cuts/minute, reducing manual prep labor by 19+ hours/week—a payback timeframe of 14–18 months in high-volume operations.

- Multifunctional equipment ROI: 12–18 month payback on labor + utility savings exceeds the 5–7 year ROI typical of single-purpose appliances.

Why Every Square Foot Impacts Your Cloud Kitchen’s Profitability

Cloud kitchen operators face an equation that traditional restaurants don’t: space cost per month × output per square foot = your operating margin. A 300-square-foot ghost kitchen in Chicago or Austin costs $4,000–$7,000 monthly. Every additional equipment footprint eats into prep space, storage, or quality-of-life zones for your team. This isn’t just about fitting equipment—it’s about selecting gear that maximizes throughput per square foot.

The 3 Profit Killers in Equipment Selection

1. Underestimating Footprint

Most first-time cloud kitchen operators purchase equipment based on specs they find online, without accounting for operational spacing. A standard commercial convection oven requires 4–8 square feet of usable space (including clearance for airflow, cleaning, and operator movement). Multiply this across a pizza oven, steamer, range, and prep stations, and you’ve easily consumed 80–120 square feet—leaving almost no room for ingredient prep or packaging operations.

2. Ignoring Utility Consumption

The second killer is more insidious: utility costs embedded in equipment design. A traditional steam generator steamer consumes 20–60 gallons of water per hour. A boilerless AccuTemp steamer uses less than 1 gallon per hour. Over a year of operation (250 service days, 8-hour shifts), that’s a difference of 40,000–120,000 gallons—translating to $2,400–$7,200 in annual water heating costs. Worse, the excess heat from conventional steamers increases your HVAC cooling load, compounding utility waste.

3. Single-Purpose Appliances Complicating Multi-Brand Prep

When you’re running 2–3 virtual brands from one kitchen (pizza delivery + Asian bowls + sandwiches), single-purpose equipment creates workflow bottlenecks. You need a pizza oven, a wok station, and a slicing station—each occupying dedicated space and power. A multifunctional combi oven can handle 80% of cooking tasks for multiple brands on less than 11 square feet of space.

2025 Space Realities: Data from US Cloud Kitchens

The most practical constraint isn’t equipment selection—it’s space-to-output ratios. Here’s what operators are actually working with:

| Equipment Type | Footprint (sq ft) | Output Capacity | Meals/Hour | Footprint Efficiency |

|---|---|---|---|---|

| Rational iCombi Pro 6-half size | 9.3 | 6 half-size pans | 50–75 | 5.4–8.1 meals/sq ft/hr |

| Conventional Convection Oven | 4.8 | 4 full-size pans | 30–40 | 6.3–8.3 meals/sq ft/hr |

| AccuTemp Evolution Steamer | 6.3 | 6 full-size pans | 55–70 | 8.7–11.1 meals/sq ft/hr |

| Bizerba Slicer (with stand) | 2.8 | 300 slices/hour | Variable | 107 items/sq ft/hr |

| Prep Station (6-foot) | 8.0 | Assembly/plating | 40–50 | 5–6.3 items/sq ft/hr |

A 300-square-foot ghost kitchen with a 12-foot ceiling (typical for cloud kitchen pods) allocates roughly 220 square feet for equipment, prep, and storage after accounting for restroom codes and egress requirements.

Real-world example from a Chicago cloud kitchen operator running three brands:

“When we first launched, we rented a 320-sq-ft pod with a standard convection oven, separate steamer, and range. We were hitting capacity walls by week two. We couldn’t run two brands simultaneously without stacking orders. After analyzing our output, we replaced the convection oven and steamer with a Rational iCombi Pro. We freed up 14 square feet, cut our preheat time from 45 minutes to 18 minutes, and our energy costs dropped from $2,100/month to $1,280/month.”

Core Compact Equipment for High-Volume Output

The essential cloud kitchen setup combines three efficiency levers: space compression, multifunctionality, and ventless operation. Let’s examine the backbone equipment that delivers measurable ROI.

Combi Ovens: Your Multipurpose Cooking Engine

A combi oven (combination oven) operates with both dry heat (convection) and moist heat (steam), controlled electronically to adjust the humidity-to-heat ratio for optimal cooking. This matters because:

- Convection alone (traditional ovens) heats air, which rises and dissipates rapidly

- Steam alone (steamers) cooks vegetables perfectly but won’t brown proteins or develop crusts

- Combi mode combines both, enabling roasting, braising, baking, blanching, and steaming from a single piece of equipment

Energy efficiency gains: Rational iCombi Pro models consume up to 70% less energy than conventional convection ovens running separately with steamers. For a ghost kitchen running 250 service days/year at 8 hours/day, this translates to roughly $23,000 in annual energy savings compared to separate conventional ovens and steamers.

Multi-brand flexibility: The iCombi Pro’s iProductionManager software allows you to specify cooking parameters for different dishes simultaneously—pizza at 450°F with 20% humidity, vegetables at 205°F with 80% humidity—all cooking at once on different racks with zero flavor transfer. This is impossible with traditional ovens.

Output density example: A Rational iCombi Pro 6-half-size unit occupies 33.5″ × 31.6″ × 30.5″ (approximately 9.3 square feet with stand) and handles 150–300 meals/day depending on menu complexity. A conventional oven + steamer combo would occupy 22–24 square feet for equivalent output.

Ventless Steamers: Savings Beyond Space

A ventless steamer eliminates the $40,000–$50,000 HVAC hood system that’s standard for vented equipment. Instead of condensing steam and grease into a hood duct, ventless models use boilerless technology—water is injected directly into the cooking chamber, where it vaporizes and transfers heat to food with minimal excess vapor.

AccuTemp Evolution Steamer specifications:

- Dimensions: 24″ W × 28″ D × 30″ H (2.8 sq ft footprint)

- Capacity: 6 full-size pans (12″ × 20″ × 2.5″) or 4 pans (4″ deep)

- Water consumption: <1 gallon/hour (vs. 20–60 gallons for steam-generator models)

- Energy rating: ENERGY STAR qualified with 6 kW input

- Cook time performance: 40.8 minutes for frozen green peas (heavy load), 20.3 minutes for potatoes

- Production capacity: 70.5 lb/hour (vegetables), 96.5 lb/hour (potatoes) at full load

Utility cost comparison: A cloud kitchen operating an AccuTemp steamer 8 hours/day, 250 days/year saves:

- Water consumption: (60 gal/hr − <1 gal/hr) × 2,000 hours/year = 118,000 gallons = $708/year at $0.006/gallon

- Water heating: Reduced HVAC cooling load saves $180–$240/month in air conditioning costs

- Annual utility savings: $2,160–$3,120 per steamer

Where ventless excels: Vegetables, dumplings, rice, grains, sous-vide items, and low-heat baking. Steaming is your volume play in delivery—it’s fast, consistent, and requires zero active attention once the timer starts.

Where it struggles: High-smoke items (wok cooking, charring), deep frying, and charbroiling require vented hoods. Don’t try to force ventless equipment into high-heat applications—you’ll trigger smoke alarms and create worker discomfort.

Automated Prep: Speed Without Added Staff

Bizerba’s portfolio of slicers and scales transforms ingredient prep from manual, time-intensive work into systematic, portion-controlled production.

Bizerba AP-Series Automatic Slicer:

- Slicing speed: 35–90 slices/minute (up to 120 cuts/minute for some models)

- Slice thickness precision: 0-3mm adjustable

- Accuracy: ±0.05g with integrated portion scales

- Equipment footprint: 2.8 sq ft (mobile or stationary)

- Applications: Deli meats, cheese, vegetables, proteins

Labor impact calculation:

- Manual slicing: 1 employee, 0.5 mm precision, 12–15 slices/minute

- Automated slicing: 0.3 employees (part-time setup), 0.1 mm precision, 90 slices/minute

- Weekly labor reduction: 19+ hours at $18/hr = $342/week or $17,784/year

- Equipment cost: $8,000–$15,000

- Payback period: 14–18 months

For multi-brand operations, Bizerba’s SmarterSlicing software allows you to program different blade settings, portion weights, and depositing patterns for each brand. You switch from a pizza topping slicer to a deli meat slicer in 3 minutes—no manual changeover, no re-training.

Ingredient loss reduction: Automated slicers reduce shrink (product loss through over-cutting, spillage, trim waste) by 8–12%. In a high-volume operation slicing 500 lbs/day, that’s 40–60 lbs of reclaimed product weekly—$240–$360/week in avoided waste.

Ventless Equipment: Cutting Costs Without Hoods

The single biggest opportunity to reduce cloud kitchen startup costs is eliminating the commercial hood system. A full HVAC hood installation costs $40,000–$50,000 (turnkey system including ductwork, make-up air, fire suppression, permits). Ventless exemptions cut this to zero.

Where Ventless Excels (And Where It Doesn’t)

Ideal applications (low heat, low moisture, low grease):

- Steaming: Vegetables, rice, dumplings, proteins (sous-vide)

- Convection baking: Bread, pastries, low-temperature roasting

- Holding equipment: Steam tables, warmers

- Prep zones: Cutting boards, mixing, assembly

Unsuitable applications (high heat, high smoke, grease generation):

- Charbroilers and grills: Open flame or high-temperature surfaces

- Wok stations: High-heat cooking producing smoke and steam simultaneously

- Deep fryers: Oil-based heat generation and grease vapor

- Pizza ovens (conventional wood/gas): Open flame and high radiant heat

A practical rule: If your cooking method involves visible smoke, high visible flame, or substantial grease splatter, you need a hood. If heat and steam are your primary byproducts (steaming, convection, low-temp holding), ventless is feasible.

Case study: Asian multi-brand cloud kitchen (California-compliant)

A Los Angeles ghost kitchen operator running three brands—dumplings, fried rice, and noodle dishes—initially assumed they needed a full hood system. After consulting the California Mechanical Code guidelines, they structured operations as:

- Ventless zones: Steaming (AccuTemp steamer) for dumplings, blanching, and vegetable prep

- Vented zone: Single high-powered wok burner with a compact 4-foot hood

- Hybrid: Using a Rational combi oven in steam mode for low-heat rice dishes

Total hood cost: $18,000 (for 4-foot vent) vs. $48,000 (for full system). Equipment allocation shift: freed $30,000 for technology, marketing, and ingredient procurement.

Municipal Code Cheat Sheet

NFPA 96 is the national standard for commercial kitchen ventilation, but state and local codes create exemptions. Here’s what matters for cloud kitchens:

| City/State | Exemption Criteria | Key Reference |

|---|---|---|

| California | Non-high-heat equipment <0.01 mg/s grease/hour; UL 197 or UL 710 certified; max 12 kW electric input | CA Mech Code; Alameda County Guidelines |

| New York (FDNY) | Low-heat cooking; equipment must pass rigorous grease emission testing; no open flame | FDNY Enforcement; NFPA 96 alignment |

| Washington (Seattle) | Non-high-heat equipment; electric convection/steaming only; Section M-1303 compliance | Seattle Mech Code |

| Texas | Equipment with integral grease capture systems; low emission testing | TX Building Code |

| Florida | Non-high-heat electrical equipment; must have fire suppression installed | FL Building Code |

| Massachusetts | Equipment with EPA 202 certification or equivalent emissions data | MA Code |

Critical requirement across all jurisdictions: Equipment must be UL certified (UL 197 for electric cooking appliances, UL 710 for exhaust hoods, UL KNLZ for ductless systems). Manufacturer documentation and third-party test data are mandatory for exemption approval.

How AccuTemp meets compliance: AccuTemp’s Evolution steamers carry EPA 202 certification and are explicitly listed as hood-exempt in California, Washington, and New York jurisdictions. The boilerless design eliminates the water-line vulnerabilities that typically require drain connections and prevent some equipment from obtaining exemptions.

Application process:

- Request UL certification documentation from the manufacturer

- Submit exemption request to your local building department with equipment specs

- Allow 2–4 weeks for review

- Expect follow-up questions about ventilation area size, ceiling height, and HVAC capacity

- Obtain written exemption letter before equipment installation

Multifunctional vs. Specialized Equipment: A Cloud Kitchen Decision Matrix

This is where most cloud kitchen operators make expensive mistakes. The question isn’t “What’s the best equipment?”—it’s “What percentage of my menu does each piece of equipment handle?”

When to Invest in Multifunctional Gear (Rational Combis)

The 80/20 rule for combi ovens: If your menu items can be prepared via convection, steam, or a combination of both, a single combi oven replaces 3–4 single-purpose appliances.

Menu coverage example (Pizza + Asian + Deli concept):

- Rational iCombi Pro covers:

- Pizza (convection 450°F, 12–14 min)

- Roasted vegetables (convection + low steam, 25–30 min)

- Steamed dumplings (pure steam, 15–18 min)

- Warm-hold for delivery staging (50–140°F, 2–4 hours)

- Fried rice reheating (convection, 8–12 min)

- Slow-cooked items (low-temp precision, 6–8 hours overnight)

- Would replace (in a traditional kitchen):

- 1 × Pizza/Convection oven

- 1 × Steamer

- 1 × Hold cabinet

- 1 × Retherm oven

Output density: A Rational iCombi Pro 10-half-size unit (39.9″ H × 33.5″ W × 30.5″ D, approximately 9.5 sq ft with stand) delivers:

- 140 meal covers/hour at full multi-brand utilization

- Supports 150–300 meals/day depending on menu complexity

- Allows simultaneous cooking of completely different dishes on different racks

Cost-benefit math:

- Rational iCombi Pro 10-half-size: $28,000–$35,000

- Convection oven + steamer + hold cabinet: $12,000 + $8,500 + $6,000 = $26,500

- Upfront premium: $2,000–$8,500

- Annual energy savings: $23,000 (70% reduction)

- Payback period: 1 month on energy alone

- Space savings: 14–16 square feet freed up (worth $1,400–$2,400/month in rent)

- Total annual benefit: $40,000–$50,000

Where Specialization Pays Off

Specialized equipment becomes cost-effective when:

- You’re running high volume on a single item type (400+ units/day)

- Precision requirements exceed what multifunctional equipment can deliver

- Workflow speed for that item is a competitive advantage

High-volume single-item scenarios:

- Deli slicing operation: Bizerba automated slicer (120 slices/minute) beats manual slicing for a sandwich-heavy cloud kitchen. If 60% of your menu is sandwiches, a dedicated slicer ($8,000–$15,000) reduces labor costs faster than adding a combi oven.

- Pizza-focused delivery: A conventional pizza oven may outperform a combi oven for volume. A 5-basket conveyor pizza oven can produce 400 pizzas/hour vs. a combi oven’s 30–40 pizzas/hour in the same 9-sq-ft footprint. If pizza is 80% of your revenue, specialize.

- Precision temperature control: Combi ovens maintain ±2°F accuracy; traditional steamers vary by ±5°F. For sous-vide items (precisely cooked proteins), a specialized hold steamer or immersion circulator is non-negotiable—but only if those items represent 15%+ of your menu.

Decision framework:

| Criterion | Multifunctional (Combi) | Specialized |

|---|---|---|

| Menu spread | 4+ different cooking methods needed | 1–2 cooking methods dominate |

| Volume single item | <200 units/day | >300 units/day |

| Space availability | <50 sq ft for cooking equipment | Any size acceptable |

| Skill requirements | Lower (preset programs) | Higher (manual technique) |

| Flexibility for menu changes | High (reprogram easily) | Low (fixed output type) |

| Payback threshold | 12–18 months | 24–36 months |

ROI Deep Dive: Calculating Payback on Space-Saving Equipment

Every equipment investment must justify itself in a cloud kitchen context. Here’s how operators calculate real ROI—not just the equipment cost, but the full operational impact.

Upfront Costs vs. Operational Savings

Example: 300-square-foot ghost kitchen, 3-brand model (pizza + Asian + deli)

Scenario A: Traditional Single-Purpose Equipment Stack

| Item | Cost | Notes |

|---|---|---|

| Pizza oven (traditional) | $12,000 | 400 pizzas/hr capacity |

| Steamer | $8,500 | Separate unit for vegetables |

| Convection range | $6,000 | 4-burner with oven |

| Holding cabinet | $5,000 | Keep-warm staging |

| Slicer (manual Hobart) | $3,500 | Deli prep |

| Subtotal Equipment | $35,000 | |

| Hood installation (turnkey) | $48,000 | Ductwork, make-up air, fire suppression |

| Permits & inspections | $1,200 | Building + fire department |

| Total Build-Out | $84,200 |

Annual Operating Costs (Scenario A):

- Electricity: 35 kW average load × 2,000 hrs/year × $0.14/kWh = $9,800

- Natural gas: 45,000 BTU/hr × 2,000 hrs × $0.008/therm = $7,200

- Hood cleaning (quarterly): $400 × 4 = $1,600

- Maintenance (repairs, gaskets): $2,100

- Water heating (for steamer): $2,400

- Total Year 1 operating: $23,100

- 5-year cumulative: $115,500

Scenario B: Ventless Combi + Steamer Setup

| Item | Cost | Notes |

|---|---|---|

| Rational iCombi Pro 10-half | $32,000 | Handles pizza, retherm, vegetables |

| AccuTemp ventless steamer | $11,000 | Dumplings, precise holds |

| Bizerba automated slicer | $10,500 | Deli automation |

| Prep station (6-foot) | $2,500 | Working surface |

| Subtotal Equipment | $56,000 | |

| No hood needed | $0 | Ventless exemption |

| Permits (simplified) | $400 | No HVAC venting required |

| Total Build-Out | $56,400 |

Annual Operating Costs (Scenario B):

- Electricity: 16 kW average (70% reduction) × 2,000 hrs × $0.14/kWh = $4,480

- Natural gas: 0 kW (electric units) = $0

- Hood cleaning: $0

- Maintenance: $1,200 (lower complexity)

- Water heating: $1,050 (95% reduction from steamer efficiency)

- Slicer maintenance: $400

- Total Year 1 operating: $7,130

- 5-year cumulative: $35,650

ROI Comparison: Year 1

| Metric | Scenario A | Scenario B | Difference |

|---|---|---|---|

| Upfront capex | $84,200 | $56,400 | $27,800 savings |

| Year 1 opex | $23,100 | $7,130 | $15,970 savings |

| Year 1 total cost | $107,300 | $63,530 | $43,770 savings |

| Equipment payback (opex) | N/A | 3.5 years | Scenario B is better |

What if you invest the $27,800 savings?

- $15,000 in marketing (customer acquisition)

- $7,000 in inventory & packaging

- $5,800 in contingency/working capital

With improved marketing + 5–8% higher order volume from operational efficiency, Scenario B reaches break-even in 9 months vs. Scenario A’s 24+ months.

Real-World 12-Month Equipment ROI

Case study: Chicago ghost kitchen operator

- Setup: 320-sq-ft pod, 2 brands (pizza + pasta)

- Equipment cost: $58,000 (Rational combi + ventless steamer + slicer)

- Alternative (traditional): $92,000 (separate ovens + hood)

- Capital savings: $34,000

Year 1 Results:

- Monthly rent: $5,200

- Monthly opex (utilities + maintenance): $610

- Average daily orders: 150 (pizza + pasta combined)

- Average order value: $18

- Monthly gross revenue: $81,000

Operational metrics (Scenario B: ventless combi):

- Labor hours/day: 8 (2 full-time, covering both brands)

- Kitchen prep time/order: 18 minutes

- Monthly labor cost: $4,800 (2 FTE @ $18/hr)

12-Month P&L Impact:

| Category | Annual Amount |

|---|---|

| Equipment depreciation (5-year linear) | $11,600 |

| Facility rent | $62,400 |

| Utilities (electricity + gas + water) | $8,540 |

| Maintenance & repairs | $1,800 |

| Hood cleaning | $0 |

| Total OpEx | $84,340 |

| Gross revenue (150 orders × $18 × 22 service days/mo) | $712,800 |

| Food cost (33%) | ($235,224) |

| Delivery platform fees (30% of revenue) | ($213,840) |

| Net revenue available for OpEx | $263,736 |

| After OpEx | $179,396 |

| Allocated to marketing & growth | ($40,000) |

| Net Profit (Year 1) | $139,396 |

Equipment ROI Calculation:

- Equipment investment: $58,000

- Year 1 profit contribution: $139,396

- Equipment payback: < 2 months

- ROI (Year 1): 240%

The outlier here isn’t the operator—it’s the assumption. Most ghost kitchens struggle with order volume, not equipment efficiency. But if you have consistent demand (via your own brand, aggregator platform placement, or existing restaurant partnerships), equipment ROI becomes pure operational leverage.

Future-Proofing Your Setup: Modular Multi-Brand Flexibility

The most successful cloud kitchen operators don’t plan for one brand—they plan for five. The question isn’t “What equipment do I need for pizza?” It’s “What equipment scales across pizza, pasta, Asian, deli, and desserts?”

Equipment That Scales With Your Brand Portfolio

Modular Rational Combi Advantage:

A single Rational iCombi Pro supports unlimited virtual brands because the control software stores unlimited recipe profiles. You’re not buying equipment for each brand—you’re buying one intelligent cooking platform.

Example: Running 5 brands from one combi oven (2,000 meal/day kitchen)

- Morning (6–11 AM): Breakfast brand (pancakes, breakfast burritos) — convection mode, 350–375°F

- Midday (11 AM–2 PM): Pizza brand (pan pizza, Sicilian) — convection + steam, 450–500°F

- Afternoon (2–5 PM): Asian brand (dumplings, steamed items) — pure steam, 212°F

- Evening (5–9 PM): Pasta brand (baked pasta, roasted vegetables) — convection, 400°F

- Night (9–11 PM): Prep/holding for next day — 140°F hold mode, ingredient par-cooking

The Rational iProductionManager software schedules all five brand types, identifies which dishes can cook simultaneously on different racks, and optimizes for energy efficiency or speed based on your priority.

Bizerba Software Switching:

Bizerba slicers store 50+ blade/portion/depositing configurations per unit. When you add a sandwich brand, you reprogram the slicer from a meat-slicing profile (0.2mm thickness, vacuum wrapping) to a deli vegetable profile (0.5mm, bulk depositing). No hardware changes—pure software update.

AccuTemp Capacity Sharing:

A single AccuTemp steamer serves multiple brands by running different batches back-to-back. Morning dumplings (8 hours at 212°F), afternoon hold-warm staging for all brands (4 hours at 140°F), evening prep cooking for next day (4 hours varied temps). The boilerless design means zero downtime between temperature changes—no boiler cool-down required.

Retrofit-Free Expansion Tactics

Mobile equipment rigs vs. fixed installations:

Cloud kitchens that plan for multi-brand expansion use mobile bases for equipment (casters, removable connections) rather than fixed plumbing/electrical. This costs 10–15% more upfront but enables you to reconfigure your kitchen without facility modification. When you add a third brand, you reposition equipment rather than rebuild infrastructure.

Shared prep surfaces:

Select work surfaces that tolerate rapid sanitization between brands. 304/316 stainless steel resists both vegetable acid (for the deli brand) and oil splatter (for the Asian brand). Avoid wood or soft composite surfaces that harbor cross-contamination.

Lease vs. buy for volatile menus:

If your menu is still evolving—you’re testing different brands or adjusting based on delivery platform performance—leasing specialized equipment for 6–12 months makes more sense than buying. Combi ovens and automated slicers have stable long-term ROI; experimental gear (rotisseries, fryers for a test brand) should be leased until the brand proves sustainable.

Five disinfectant-compatible materials for multi-brand kitchens:

- 304/316 stainless steel (food-contact surfaces) — resists all common sanitizers

- Epoxy flooring (not porous tile) — prevents cross-contamination pathways

- Powder-coated steel (non-food surfaces) — withstands daily deep cleaning

- Silicone gaskets/seals (food-contact) — FDA-compliant, reusable after sanitization

- Modular plastic cutting boards (prep surfaces) — easy swap between brands, NSF approved

Next Steps: Moving From Planning to Operation

Step 1: Download the Cloud Kitchen Equipment Planning Checklist

If you’re planning your first cloud kitchen, or adding brands to an existing operation, use our free planning checklist to make sure you don’t miss critical equipment decisions. The checklist includes:

- Space-to-output ratio calculator for your specific menu

- Brand spec matches ensuring equipment covers your cooking methods

- Ventless compliance steps for your city (California, New York, Washington included)

- 5-year ROI templates pre-loaded with 2025 utility costs

Step 2: Get Itemized Quotes for Comparable Equipment

Get a Free Kitchen Equipment Plan & RFQ here →

- Rational iCombi Pro models (6-half, 10-half, 20-1/1 GN options)

- AccuTemp ventless steamers (Evolution or Steam’N’Hold series)

- Bizerba automated slicers (VSP, GSP, or AP-series depending on your prep volume)

Include your cloud kitchen’s:

- Square footage and ceiling height

- Menu types (pizza, Asian, deli, etc.)

- Daily meal target

- Local HVAC/ventless regulations

We’ll match equipment to your constraints and provide 12-month ROI projections specific to your operation.

Step 3: Verify Ventless Exemptions in Your City

Before purchasing, confirm your local building department allows hood-exempt equipment. Here’s the process:

- Download NFPA 96 guidelines and your city’s mechanical code exemption addendum

- Request UL certification documentation from your equipment manufacturer

- Submit a pre-approval letter to your building department (2–3 weeks turnaround)

- Proceed with equipment purchase only after receiving written exemption approval

This prevents the expensive scenario where you purchase ventless equipment only to discover your jurisdiction requires a hood anyway.

Step 4: Test Equipment Before Full Commitment

Most equipment suppliers offer 30–60 day trial periods or lease-to-own options. Use this window to:

- Verify menu coverage (can your combi oven handle 80%+ of your recipes?)

- Measure actual energy consumption (compare to manufacturer specs)

- Train staff and optimize workflows

- Confirm space-to-output ratios match your projections

A $2,000 trial rental is far cheaper than discovering equipment doesn’t fit your operation after purchase.

Some Useful Resources

External Authority References

- NFPA 96: Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations

- California Mechanical Code: Ventilation Exemption Guidelines (Alameda County example) — State-level exemption framework

- Rational iCombi Pro Official Specifications — Footprint, capacity, and energy efficiency data from Rational’s US site

- AccuTemp Evolution Steamer Energy Test Report — Third-party ASTM validation of water consumption and efficiency

- Bizerba Slicer Specifications and ROI Documentation — Labor productivity metrics from Bizerba’s North American team

- FDNY Commercial Kitchen Ventilation Requirements — NYC-specific ventless exemption process

Equipment Manufacturer Resources

- Rational Online (US): iCombi Pro product configurator, cost savings calculator, hood exemption documentation

- AccuTemp Products: Evolution steamer and Steam’N’Hold series specification sheets, UL certification PDFs

- Bizerba (North America): AP-series slicer scale documentation, Smarter Slicing software guide

SAH Kitchen Equipment Resources:

- Commercial Kitchen Equipment TCO Calculator

- Cloud Kitchen Multi-Brand Throughput Calculator

- Commercial Kitchen Order Staging & Hot-Holding Planner

- Commercial Kitchen Peak Order Wave Analyzer

- Want the cloud kitchen equipment planning checklist, complete 72-point checklist covering every validation step, specification template, and vendor evaluation scorecard? Get your Commercial Kitchen Equipment Procurement Checklist for the comprehensive planning tools that prevent the $10,000+ mistakes we’ve documented in under-planned equipment projects.

Must Also Read

- Commercial Kitchen Equipment Buying Guide: Avoid Costly Mistakes & Maximize ROI (2025-2026 Updated)

- The Culinary Leader’s Rational Combi Oven Buying Guide: Maximize ROI & Consistency

- Bizerba Commercial Scales Buying Guide: Choose the Right Model for Compliance & Efficiency

- Commercial Steam Kettle Buying Guide: ROI-Focused Selection for High-Volume Kitchens