Reading Time: Approximately 15 minutes

Rising regulatory pressures and labor cost inflation are squeezing margins across retail food operations. Fresh departments—delis, bakeries, meat sections—face an uncomfortable reality: every gram of product giveaway eats into profit. At the same time, weights and measures inspectors are tightening enforcement, and a single miscalibrated scale can result in fines, customer disputes, or operational shutdowns. This guide cuts through the complexity and gives you a 5-step framework to select the right Bizerba commercial scale that minimizes product waste, integrates seamlessly with your POS system, and passes every compliance audit.

Key Takeaways

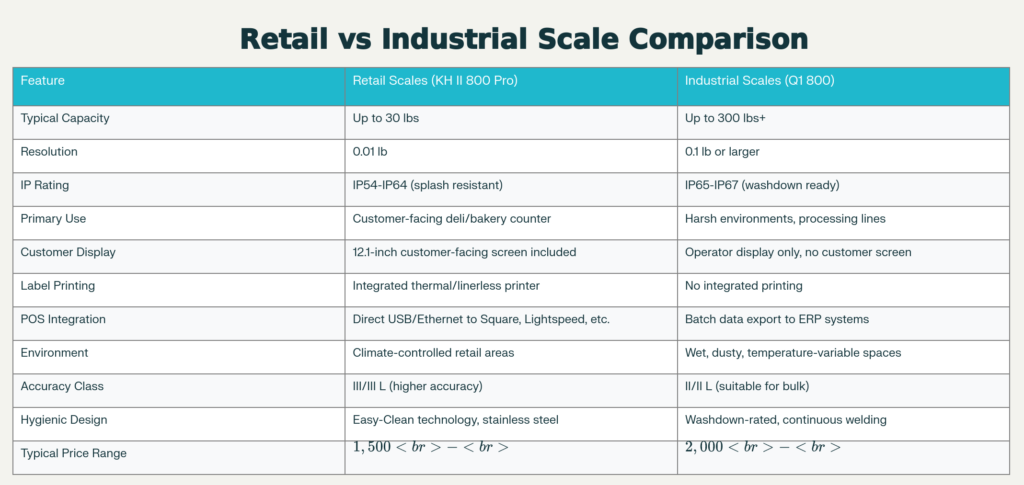

- Scale classification matters: Retail PC scales like the KH II 800 Pro suit high-volume deli/bakery counters; industrial models like the Q1 800 handle harsh processing environments.

- Accuracy directly impacts costs: A 0.5% improvement in portioning accuracy can save a busy deli $10,950+ per year on premium items alone.

- NTEP certification is non-negotiable: Most U.S. states require NTEP (National Type Evaluation Program) certification for any scale used in commercial sales transactions.

- POS integration streamlines operations: Modern Bizerba scales connect directly to Square, Lightspeed, and other platforms, reducing manual entry errors by up to 22%.

- Proper installation and calibration determine inspection success: A documented calibration procedure and pre-audit self-check eliminate surprise failures.

Scale Classification 101: Retail vs. Industrial Scales for Food Businesses

The first decision separating successful operations from costly mistakes is understanding which type of scale you actually need. “Retail” and “industrial” scales are built for completely different jobs, and choosing wrong will saddle you with either wasted features or insufficient durability.

Retail scales—like the Bizerba KH II 800 Pro—are designed for customer-facing transactions. They sit on your deli counter or bakery display, weigh products in front of customers, print labels, and ring up sales on the spot. These scales prioritize ease of use, fast label printing, and integrated POS connectivity. They’re designed for climate-controlled environments where staff control the weighing process and the scale must communicate clearly with both operators and customers.

Industrial scales—like the Bizerba Q1 800 and platform scales—are engineered for harsh, high-volume processing. They live in meat-cutting rooms, bulk receiving areas, and processing lines where washdown is routine, temperatures fluctuate, and the scale endures constant use. Resolution is often coarser (because bulk weight tolerances are wider), but durability and protection against moisture and dust are paramount.

Choosing between them requires mapping your actual weighing points.

Front-of-House vs. Back-of-House: Mapping Your Weighing Points

Retail vs. Industrial Scale Comparison: Key Specifications and Use Cases

A typical supermarket deli operation has at least two distinct weighing workflows:

- Front-of-house (counter scale): Customers order sliced ham, cheese, or prepared items. Staff weighs in front of the customer, applies a label with price and nutritional info, and rings the sale into the POS. A retail PC scale like the KH II 800 Pro excels here. Its 12.1-inch customer display builds confidence in accuracy, the integrated printer applies compliant labels instantly, and direct USB/Ethernet connection to POS eliminates manual price entry.

- Back-of-house (prep/bulk scale): Staff receives bulk deliveries, portions meat or cheese into smaller units for storage, or portions components for batch recipes. These scales can be smaller (compact precision scales) or larger platform models depending on throughput. They don’t need customer displays or label printers—they need durability, washdown protection, and batch data logging.

A supermarket chain with five locations serving approximately 500 customers per day per store would see dramatic efficiency gains from deploying the right scale type in each zone. Pairing a high-end retail PC scale on the counter with a washdown-rated compact scale in the prep room ensures both compliance and operational speed.

When to Upgrade to Industrial-Grade Scales

Warning signs that your current retail scale is inadequate for back-of-house duties include:

- Frequent recalibration requests: If your service tech is recalibrating more than annually, the scale is being abused by its environment (water splash, temperature swings, dust).

- Environmental damage: Corrosion on the housing, moisture inside the display, or staining indicates IP-rating inadequacy.

- Batch error patterns: If prep staff report inconsistent weights or missing data logs, the scale’s connectivity or memory is stressed.

When these symptoms appear, it’s time to migrate back-of-house weighing to Bizerba’s industrial platform scales. These models feature stainless steel construction, IP65–IP67 ratings for washdown environments, and robust data logging for batch traceability. The upfront investment ($2,000–$8,000) is recouped through reduced downtime, fewer recalibration visits, and improved traceability during health inspections.

Accuracy & Compliance: Meeting NIST Handbook 44 Standards for Food Sales

The second major decision lever is accuracy class. This is where regulatory reality and cost reality collide. Weights and measures regulators don’t care about your profit margin—they enforce NIST Handbook 44, which sets maximum permissible error (MPE) limits based on scale class.

For deli and fresh-retail scales, two accuracy classes dominate:

- Class III scales: Maximum permissible error of ±0.5% of the indicated weight. Suitable for products sold by weight where high accuracy is required (deli meats, cheeses, prepared salads).

- Class III L scales: Even tighter tolerances (±0.2% to ±0.3%), designed for high-volume retail where consistent customer trust is essential.

The practical implication: A Class III scale reading 2 lbs can be off by as much as ±0.01 lb (0.16 oz) and still be legal. A Class III L scale must be within ±0.004 lb. For a customer buying premium ham at $12/lb, that difference—0.016 lb—is a 19-cent variance per transaction. Over a year, it compounds into thousands of dollars.

Annual Cost of Scale Inaccuracy: Premium Ham Sliced at Deli Counter

A supermarket deli selling 500 lbs of premium sliced ham daily faces these cost realities:

- At 1.5% over-portioning (poor scale accuracy): $32,850 annual loss on a single item.

- At 1.0% over-portioning (industry average): $21,900 annual loss.

- At 0.5% over-portioning (excellent accuracy): $10,950 annual cost.

The difference between a poor scale and an excellent one is $21,900 per year on ham alone. Extend this to cheese, prepared salads, and seasonal products, and annual giveaway across a 5-store chain can easily exceed $100,000.

NTEP Certification: Non-Negotiables for Legal-for-Trade Scales

NTEP (National Type Evaluation Program) certification is not optional—it is mandatory in most U.S. states for any scale used to sell products by weight. An NTEP Certificate of Conformance (CC) is your proof that the model has been independently tested and verified to meet national accuracy and design standards.

What NTEP certification proves:

- The scale model has been tested by an accredited third-party lab against NIST Handbook 44 standards.

- It maintains accuracy across its full capacity range (linearity test).

- It performs consistently regardless of load position on the platform (shift/corner test).

- The manufacturer’s design prevents fraud (sealed adjustment points, etc.).

What NTEP does NOT prove:

- That your specific unit is currently in calibration (it must be verified on-site by a weights and measures officer).

- That the scale is suitable for your environment (you must ensure adequate ventilation, stable surfaces, etc.).

- That installation was done correctly (improper sealing or cabling voids compliance).

How to verify NTEP status:

- Go to the National Conference on Weights and Measures (NCWM) website at ncwm.com.

- Search their NTEP Certificates of Conformance database by manufacturer, model number, or certificate number.

- Download the actual certificate—it will specify:

- Accuracy class and maximum permissible errors

- Capacity and readability (resolution)

- Whether it applies to the complete scale or only certain components (e.g., indicator, platform)

- State approval status (some states have variations)

For Bizerba scales, NTEP certificates are published for each model variant. For example, the KH II 800 Pro series carries NTEP certification in Class III L, confirming its suitability for retail deli sales. Similarly, Q1 800 industrial models have their own certificates specifying their class and capacity ranges.

Red flag: If a vendor claims “NTEP certified” but can’t provide a certificate number or direct you to the NCWM database, do not purchase. Counterfeit NTEP claims are not uncommon in online retail, and buying an uncertified scale exposes you to fines and transaction disputes.

The Real Cost of Scale Inaccuracy

Scale accuracy is not an abstract specification—it directly impacts cash flow. Here’s how:

Example calculation for a 5-store deli chain:

Assume:

- 500 customers per store per day × 5 stores = 2,500 transactions daily

- Average transaction: 0.75 lbs of mixed items (meats, cheeses, prepared foods)

- Average price: $10/lb

- Current scale accuracy: 1.0% over-portioning (industry average)

Annual giveaway:

- 2,500 transactions × 365 days × 0.75 lbs × 1.0% = 6,844 lbs over-portioned

- 6,844 lbs × $10/lb = $68,440 annual loss

If you upgrade to a Class III L scale at 0.5% over-portioning:

- New annual giveaway: 3,422 lbs × $10/lb = $34,220

- Annual savings: $34,220

A Bizerba KH II 800 Pro costs approximately $2,000. This upgrade pays for itself in 21 days of operation. Within one fiscal quarter, the ROI becomes obvious, and stakeholders stop questioning the investment.

Smart Scale Features Explained: How Bizerba’s AI Reduces Shrink & Labor Costs

Modern commercial scales have evolved beyond simple weight readout. Bizerba’s software ecosystem integrates AI-powered features that tackle the two biggest pain points in fresh retail: portion consistency and labor cost.

AI-Powered Portion Control & Waste Tracking

Predictive tare and PLU learning are not marketing hype—they are operational tools that measurably reduce waste.

When an employee places a deli container on a retail PC scale like the KH II 800 Pro, the scale can:

- Recognize the container (via weight signature or barcode integration) and automatically tare it out (subtract its weight).

- Suggest the likely product (via AI-backed PLU lookup based on recent history) so the employee doesn’t manually select from a list of 200 items.

- Flag over- and under-portions with instant visual alerts (red/yellow/green traffic lights) based on preset portion targets.

Labor impact: A bakery in the Pacific Northwest reported a 22% reduction in labor hours in their scaling and labeling station after deploying Bizerba’s RetailPowerScale software with auto-PLU lookup. Staff no longer had to scroll through long product menus—they simply confirmed the AI suggestion and moved to the next customer.

Waste reduction: The same facility tracked portion adherence data and discovered that 40% of over-portions occurred during morning rush hours when tempo was fastest. By adjusting staff rotations and adding a second scale during peak times, they reduced morning giveaway by 12%.

Bizerba’s Labeling Center software goes further, enabling centralized label design and real-time template updates across multiple stores. If your deli discovers a labeling error (e.g., missing allergen info or incorrect nutrition facts), you push a single software update, and every scale in your chain prints the corrected label immediately. No reprinting of pre-printed labels, no waste.

Automated Labeling Compliance for Allergen Management

Federal regulation (FDA Food Labeling Guide and USDA protocols) requires that packaged deli items clearly disclose:

- Net weight/quantity

- All major food allergens (milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat, soy, sesame)

- Ingredient list

- Nutritional information (for certain categories)

Manual label printing is error-prone. Staff rushes, forgets to include “Contains: milk” on a ham/cheese combo, and a customer with a dairy allergy reacts. Lawsuits, recalls, reputation damage.

Bizerba’s integrated USDA/NLEA label templates eliminate manual entry:

- Select the product (e.g., “Honey-Roasted Turkey Slices”) from the PLU database.

- The scale automatically inserts the correct allergen warnings, weight, and price.

- The printer applies the label to the item.

This workflow reduces labeling errors by up to 95% according to bakery and deli operators using the system. More importantly, it ensures that every label is legally compliant, eliminating a major liability vector.

Bizerba Scale Models Decoded: Match Your Operation Type to the Right System

Bizerba’s product line spans retail, compact, and industrial categories. Matching your operation to the right model prevents over-spending (buying industrial durability for a small bakery) and under-performing (forcing a high-volume deli to rely on consumer-grade equipment).

Supermarket Fresh Departments: KH II 800 Pro & K3 Flex

The Bizerba KH II 800 Pro is purpose-built for high-volume deli and bakery counters. Here’s what makes it the go-to choice:

Specifications:

- Capacity: Up to 30 lbs (14 kg)

- Resolution: 0.01 lbs (adjustable to grams)

- Accuracy Class: Class III L (±0.3% tolerance)

- Processor: Intel Quad-Core with 64-bit Windows/Linux

- Display: 12.1-inch operator + 12-inch customer display (optional)

- Printer: Integrated thermal printer (receipt and linerless label capable)

- Connectivity: USB, Ethernet, optional WLAN

- IP Rating: IP54 (splash-resistant, not washdown-rated)

Why it dominates retail deli environments:

- POS integration: The scale communicates directly with Square, Lightspeed, Toast, and other restaurant/retail platforms. A customer orders 0.75 lbs of ham, the scale weighs it, transmits the weight and product code to the POS, and the register automatically calculates the price. No manual typing, no errors.

- Hygienic design: The “Easy Clean” display and removable platters mean staff can sanitize between items without fear of water damage. Stainless steel components resist corrosion from daily washdowns.

- Linerless printing: Customers increasingly expect minimal waste. Linerless label rolls have no carrier paper, reducing label waste by 75%. The integrated autocutter with durable blade ensures consistent label length.

- Rapid boot times: In a busy lunch rush, every second counts. The KH II 800 Pro boots in seconds and can recover from accidental shutdowns without staff intervention.

Typical deployment: A 30,000 sq. ft. supermarket deli counter would use 2–3 KH II 800 Pro units (one per section: meats, cheeses, prepared foods) running RetailPowerScale software with synchronized PLU databases.

Specialty Shops & Bakeries: Compact Precision Scales

For boutique delis, cheese shops, or artisan bakeries, Bizerba’s compact precision models (like the CP5) offer space-saving accuracy without the price tag of a full PC scale.

Specifications:

- Capacity: 5 lbs (2.2 kg)

- Resolution: 0.01 oz (very fine for premium products)

- Accuracy Class: Class III L

- Design: Standalone bench scale (no integrated display or printer)

- Connectivity: Optional USB for label printer

- IP Rating: IP54

Why they suit specialty retail:

- Counter real estate: A high-end cheese counter has limited space. The compact footprint allows multiple scales on one surface or allows staff to move the scale between stations.

- Premium accuracy: Artisan products (aged Parmigiano, hand-tied sausages, specialty olive mixes) command high prices. A 0.05 oz difference can be significant. Compact precision scales deliver Class III L accuracy in a portable form.

- Label printing flexibility: A USB connection to a portable label printer allows staff to apply labels at different locations, ideal for shops with rotating displays.

Typical deployment: A 2,000 sq. ft. specialty cheese shop might use 1–2 compact scales as the main weighing station, plus a networked label printer.

Food Processors & Central Kitchens: Q-Series Industrial Scales

For large-scale meat processors, central commissaries, or food manufacturing, Bizerba’s Q-series industrial scales provide the durability, throughput, and integration required.

Specifications:

- Capacity: Up to 300 lbs (140 kg) or more

- Resolution: 0.1 lbs or larger (coarser, appropriate for bulk)

- Accuracy Class: Class II or Class II L (suitable for non-retail transactions)

- Design: Fixed platform scale with separated indicator

- Connectivity: RS-232, Ethernet for integration with MES and ERP systems

- IP Rating: IP65–IP67 (fully washdown-rated)

- Material: Stainless steel with continuous welding (bacteria and corrosion resistant)

Why they dominate processing lines:

- Overload protection: Meat processing involves high-volume handling. The scale survives accidental drops of heavy containers or full crates without drift or damage.

- Batch data logging: The scale can log each weighing event with timestamp, operator ID, and product code. This data integrates directly into batch records, supporting HACCP and traceability compliance.

- Washdown durability: Processing facilities hose down equipment daily. An IP67 scale withstands high-pressure water jets without moisture entering the load cells or electronics.

Typical deployment: A 50,000 lb/day meat processor would use 3–5 Q-series scales positioned at receiving (incoming lot verification), pre-processing (portion sizing), and final packing (quality verification).

5 Must-Check Scale Features for Compliance & System Integration

Beyond model selection, a few critical features determine whether your scale will pass inspection and integrate smoothly into your operation.

Feature 1: Legal-for-Trade Documentation & Sealing

Every NTEP-certified scale arrives from the manufacturer with adjustment points that are sealed to prevent tampering. The seal indicates that the manufacturer has calibrated the scale to factory standards. In most states, a scale that has been unsealed without proper authorization cannot be used for legal-for-trade transactions.

Installation compliance checklist:

- Keep the manufacturer’s seal intact until a licensed scale technician installs the unit.

- Have the technician verify the NTEP CC number matches the unit’s nameplate.

- Request a calibration certificate that documents:

- The date and time of calibration

- The technician’s credentials (license number, company)

- Test weights used and their calibration status

- Results of accuracy tests at minimum and maximum capacity

- Secure the documentation in a binder with photos of the installation (location, level surface, ventilation clearance).

When a weights and measures officer arrives for an inspection, the first thing they check is whether the seal is intact. A broken seal without documentation = failed inspection.

Feature 2: Network & POS Compatibility

A Bizerba retail scale’s value depends entirely on whether it can talk to your POS system. Incompatibility = manual price entry = errors.

Compatibility testing checklist:

| POS System | Supported Scales | Connection Type | Notes |

|---|---|---|---|

| Square | CAS, Ohaus, Digi | USB or Ethernet | Requires compatible scale model |

| Lightspeed | Select Hyperspace-integrated models | USB or API | Lightspeed POS supports limited scale models via Hyperspace integration |

| Toast | Ohaus, Avery Weigh-Tronix | Ethernet | Requires API configuration |

| Bizerba RetailPowerScale | All Bizerba PC scales | Ethernet/USB | Native, seamless integration |

Before purchasing a Bizerba scale:

- Confirm your POS vendor explicitly supports Bizerba models (or confirm Bizerba’s RetailIntegratorsKit compatibility).

- Request a test drive: Deploy the scale in your environment for 48 hours before final purchase.

- Document the data flow: Does the weight transmit correctly? Does the product code sync? Are prices calculated accurately?

A $200 error in POS incompatibility can cost thousands in downtime and staff frustration.

Feature 3: HACCP & Food Safety Material Standards

Commercial food scales must meet NSF (National Sanitation Foundation) standards and/or 3-A standards (established by ASME and NSF for dairy and food equipment).

Material requirements:

- Stainless steel: 304 or 316 grade, resistant to corrosion and bacteria.

- ABS plastic: Food-grade, resistant to sanitizing chemicals and high temperature.

- Removable components: Platters and displays must be removable for deep cleaning.

Bizerba’s retail scales meet NSF 8 and NSF 169 standards, ensuring they are safe for direct food contact environments. Industrial scales often carry NSF 4 (equipment with indirect food contact).

Inspection implication: A health inspector may ask for NSF certification documentation. If your scale can’t provide it, the inspector may require isolation from food contact areas, limiting operational flexibility.

Implementation Roadmap: Getting Your Bizerba Scale Inspection-Ready

The final step—and the one most operators skip—is a structured implementation plan. Rushing deployment invites compliance failures that can cost thousands in fines and downtime.

Pre-Installation Site Checklist

Before the scale technician arrives, prepare your location:

- Level surface: Use a bubble level to verify the installation location is level within ±2 degrees. Unlevel floors cause shift errors (the scale reads differently depending on where the load sits on the platform).

- Stable support: Ensure the surface can bear the scale’s weight plus maximum load without vibration. Avoid placing scales near doors, walkways, or HVAC vents that create air currents.

- Electrical and network access: Retail PC scales require 110V power and either USB or Ethernet connectivity. Ensure cables are routed safely and not subject to damage or unplugging.

- Clearance around platform: Leave 6 inches of clearance on all sides to prevent scale drift caused by surrounding objects.

- Environmental documentation: Take photos of the installation location, network setup, and power source. File these with your compliance documentation.

Day 1 Inspection Prep: Self-Audit Steps

Before a weights and measures officer schedules an official visit, conduct a self-audit:

Documentation binder should include:

- NTEP Certificate of Conformance (downloaded from NCWM database)

- Calibration certificate from licensed technician (dated within last year)

- Photos of installation location and configuration

- Records of any adjustments or service (with dates and technician credentials)

- Training sign-off sheets from staff (confirming they understand the tare function, label printing, etc.)

Performance self-tests:

- Linearity test: Weigh known test weights at 25%, 50%, 75%, and 100% of scale capacity. Accuracy should be within tolerance at all points.

- Shift/corner test: Place the same known weight at the four corners of the platform. Readings should vary by no more than the maximum permissible error. (For a Class III L scale weighing 1 lb, variation should be ±0.005 lb or less.)

- Zero check: Ensure the scale returns to zero after each weighing with no load on the platform.

If any test fails, stop using the scale for transactions immediately and contact a licensed technician. Running a scale that fails calibration is not only illegal—it exposes you to liability if a customer claims they were overcharged.

Staff Training: The Often-Forgotten Step

A perfectly calibrated scale fails in the hands of untrained staff. Allocate time for hands-on training:

- Tare function: Staff must understand how to tare out containers, avoid double-tareing, and reset the scale between customers.

- Product selection: Train on how to select products correctly so the label prints with accurate allergen and nutritional information.

- Label application: Ensure labels are placed on items clearly visible to customers and in a position that won’t rub off during handling.

- Escalation procedures: If a customer disputes a weight, what do they do? Can they re-weigh the item? Is there a dispute resolution protocol?

A 30-minute group training session plus individual shadowing prevents most operational errors and accelerates the learning curve for new hires.

Cost-Benefit Analysis: When to Replace Your Scales

The decision to replace aging scales shouldn’t be emotional—it should be financial.

Key ROI drivers:

- Reduced product giveaway: As demonstrated earlier, a 0.5% improvement in portioning accuracy pays back the scale cost in 3–6 months for a busy deli.

- Lower labor costs: Automation (auto-PLU, auto-tare, quick labeling) reduces labor hours by 15–25% in high-volume environments.

- Reduced compliance costs: Scales out of calibration incur frequent service calls. Proper scales reduce service costs by 60–80% annually.

- Avoided fines: A single weights and measures violation can cost $500–$2,000 in fines, plus mandatory re-inspections. Prevention is far cheaper than remediation.

Replacement trigger:

- If your current scales are more than 5 years old and require service more than once annually, they are candidates for replacement.

- If your annual giveaway (measured by actual shrink data) exceeds 1.5%, upgrading to a Class III L scale will pay for itself within 18 months.

Next Steps: Download Your Scale Selection Toolkit

Selecting the right scale model shouldn’t require weeks of research. We’ve created two downloadable resources to accelerate your decision:

- Commercial Scale Compliance & Integration Checklist: Use this during your pre-installation phase to ensure NTEP validation, POS compatibility testing, and documentation readiness.

- Scale Selection Matrix: Answer five simple questions about your operation (daily transaction volume, average item weight, POS platform, hygienic requirements), and the matrix recommends which Bizerba model (or category) is optimal for your use case.

Both resources are free and available for immediate download. Whether you’re a single-location specialty shop or a multi-store grocer, these tools cut through the complexity and keep you on track toward inspection-ready deployment.

Ready to upgrade your scales? Request a complimentary quote from our Bizerba partners, or reach out to our team to discuss your specific operation’s needs.

Useful Resources

To deepen your knowledge of commercial scale standards, compliance, and Bizerba solutions, consult these authoritative sources:

Internal Guides:

External Authority & Standards:

- NIST Handbook 44: “Specifications, Tolerances, and Other Technical Requirements for Weighing and Measuring Devices” — the definitive federal standard for commercial weighing.

- NCWM NTEP Certificates Database: Search and verify NTEP certificates for any commercial scale model.

- FDA Food Labeling Guide: Official FDA guidance on net weight, allergen declaration, and nutritional labeling requirements.

- USDA Meat and Poultry Labeling: Regulatory requirements specific to meat, poultry, and deli products.

- NSF International Standards: Information on NSF certification and food-contact surface material standards.

Bizerba Resources:

SAH Kitchen Equipment Resources:

- Commercial Kitchen Equipment TCO Calculator

- Cloud Kitchen Multi-Brand Throughput Calculator

- Commercial Kitchen Order Staging & Hot-Holding Planner

- Commercial Kitchen Peak Order Wave Analyzer

Must Also Read

- The Culinary Leader’s Rational Combi Oven Buying Guide: Maximize ROI & Consistency

- Commercial Kitchen Equipment Buying Guide: Avoid Costly Mistakes & Maximize ROI (2025-2026 Updated)

- Commercial Steam Kettle Buying Guide: ROI-Focused Selection for High-Volume Kitchens

- Essential Cloud Kitchen Equipment: Maximizing Output in Under 500 Sq Ft (2025-2026 Guide)