Reading Time: Approximately 15 minutes

Buying commercial kitchen equipment feels overwhelming—especially when you’re doing it for the first time. You’re juggling budget constraints, compliance requirements, space limitations, and the pressure to choose equipment that will actually support your menu and growth plans. And if you make the wrong call? You could waste tens of thousands of dollars on equipment that’s inefficient, undersized, or breaks down constantly.

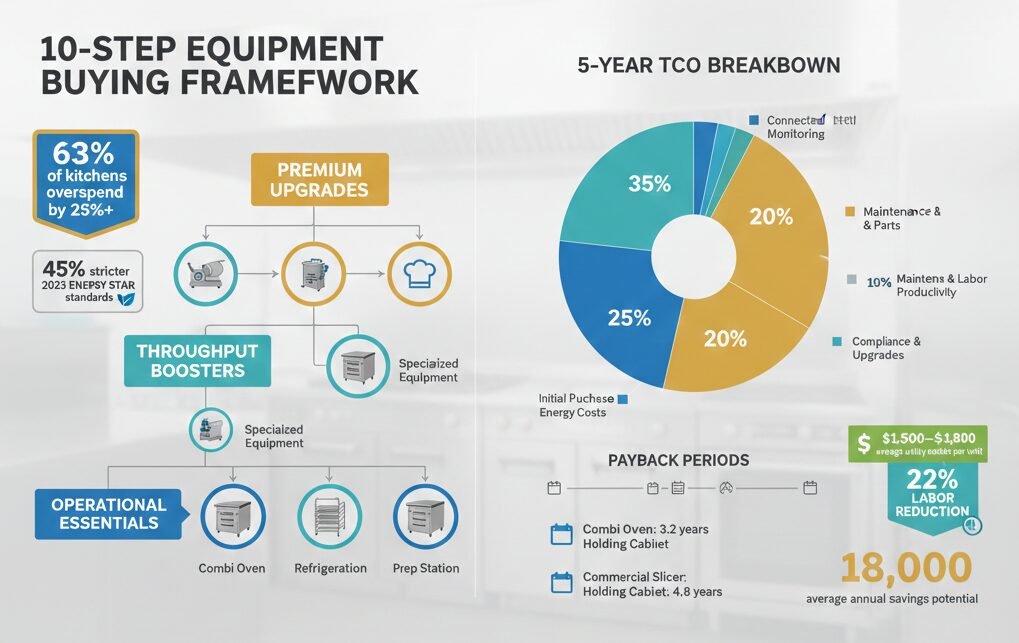

The stakes are real. According to NAFEM’s 2024 industry report, 63% of new kitchen operators overspend by 25% or more due to unplanned costs, hidden maintenance fees, and equipment that doesn’t fit their actual workflow. The good news: this buying guide walks you through a proven 10-step framework that combines 2025 compliance standards, total cost of ownership math, and practical brand comparisons so you can make confident decisions aligned with your kitchen’s future.

Whether you’re opening your first restaurant, launching a cloud kitchen, or renovating an existing operation, this guide gives you the tools, checklists, and decision frameworks that professionals use—without the guesswork.

Key Takeaways

- Overspending is common: 63% of new kitchens exceed budgets by 25%+ due to poor planning. A structured framework prevents this.

- 2025 changes the rules: Stricter ENERGY STAR benchmarks, updated NSF/ANSI 7 standards, and new ADA compliance requirements reshape what “essential” equipment means.

- TCO, not purchase price: Equipment that costs 15% more upfront can save 30% over 5 years through energy efficiency and durability.

- Brand matters in specific ways: Rational excels in combi oven flexibility; Bizerba dominates space-efficient slicing; AccuTemp leads in connected holding systems—but only where those capabilities directly solve your operational problem.

- Hidden costs kill budgets: Maintenance training, utility rebates, hood clearance, and compliance certifications must be factored in before purchase.

- Actionable tools exist: Use our compliance checklist, TCO calculator, and equipment comparison matrix to make data-driven choices instead of vendor recommendations alone.

2026 Commercial Kitchen Design Trends You Can’t Ignore

The commercial kitchen equipment landscape has shifted dramatically heading into 2026. These aren’t just cosmetic changes—they directly affect what you should buy and how you should budget.

Energy Efficiency: The New Equipment Mandate

The compliance driver: ENERGY STAR’s 2025 commercial cooking equipment benchmarks are 45% stricter than 2023 standards. This means older efficiency ratings are obsolete, and many “standard” models from legacy manufacturers no longer qualify for rebates or utility incentives that now routinely save operators $1,500+ per year.

Why this matters to you: Utility rebates are real money. A combi oven that qualifies for ENERGY STAR status (like the Rational iCombi Pro series) typically carries a rebate of $1,200–$1,800 depending on your state and utility company. That’s not optional savings—it’s rebate money sitting on the table. When you’re comparing equipment, always check ENERGY STAR certification before committing to a vendor quote.

Concrete example: An AccuTemp NS-Series ventless steamer uses 35% less energy than legacy steamer models and qualifies for California’s utility rebate program. Over 5 years, the energy savings alone amount to approximately $2,050—nearly offsetting the premium you pay upfront.

Compact Equipment = Labor Cost Savings

Space commands a premium in 2026. Rent isn’t getting cheaper, and every square foot matters—whether you’re running a cloud kitchen with 400 sq ft or a traditional restaurant squeezing prep stations into the back.

The equipment response: Manufacturers are building narrower, stackable, and more vertically oriented units. A Bizerba GS series slicer occupies 24% less floor space than comparable competitors (12.5 sq ft vs. 16.5 sq ft) while maintaining the same throughput. For multi-brand cloud kitchens or delivery-only operations, this compact footprint translates to fitting more revenue-generating equipment into the same space.

Labor multiplier: Compact equipment often pairs with built-in portion control and automation features. Bizerba slicers with auto-calculating portion weights reduce prep labor by approximately 22% compared to manual slicing, meaning one operator can handle the workload of 1.2–1.3 manual slicers. Over a year, that’s one full-time position’s worth of labor productivity gain.

Food Safety Automation & Connected Equipment

Connected equipment is moving from luxury to standard. Rational’s iCombi Pro series now includes AI-powered sanitation alerts that track cleaning cycles and notify managers when systems need attention—reducing manual inspection time and compliance risk.

Why it matters: Food safety audits and compliance documentation are labor-intensive. Equipment that auto-logs sanitization cycles and alerts you to maintenance needs reduces the administrative burden and creates audit trails that regulators expect. This is becoming table-stakes for larger operations and franchise concepts.

Compliance Deadline: NSF/ANSI 7 Updates for Refrigeration

NSF/ANSI 7 standards for commercial refrigeration were updated in late 2024 and became mandatory for new equipment in early 2025. The key changes: stricter accessibility requirements (ADA reach limits for door handles and temperature controls) and improved moisture barriers in door gaskets.

Your action: When specifying refrigeration, verify that models meet the 2025 NSF/ANSI 7 certification. Older inventory may still be in stock at discounted prices but won’t pass health inspections in most jurisdictions. This isn’t negotiable.

The 2026 Essential Equipment Shortlist (With Priority Tiers)

Forget generic equipment lists. Instead, think in tiers—starting with what you must have to operate, then layering in throughput boosters, and finally adding premium upgrades as budget allows.

Tier 1: Operational Essentials (Non-Negotiable)

Cooking flexibility: A combi oven (not just a traditional convection oven or range). Why? Combi ovens handle roasting, steaming, braising, and precision temperature cooking—meaning you can execute a broader menu with one piece of equipment. If you’re opening with $50k to spend on cooking equipment, a mid-range combi oven (like a Rational iCombi Pro) gives you far more menu options than stacking a fryer, a range, and a convection oven separately. It’s a strategic choice, not a luxury.

Safe refrigeration: NSF-certified reach-in or walk-in units meeting 2025 standards. Don’t cut costs here—failing a health inspection over a $300 refrigeration component isn’t worth it.

Prep surface: Stainless steel work tables and a commercial cutting board station. This isn’t fancy; it’s foundational.

Tier 2: Throughput Boosters (Add Based on Menu)

If your menu includes sliced proteins, charcuterie, or portioned prep: A commercial slicer dramatically increases consistency and reduces labor. Bizerba GS series slicers with auto-portion settings let one operator handle the work of 1.2–1.3 manual slicers, and the precision cuts reduce food waste. Add this if slicing is a daily bottleneck.

If you’re operating a cloud kitchen or multi-brand concept: Holding cabinets with temperature monitoring (like AccuTemp’s connected units) let you prep ahead, hold food safely, and reduce last-minute line stress. These become essential in high-volume, time-compressed workflows.

Tier 3: Premium Upgrades (As Budget Allows)

Connected monitoring: Equipment with IoT sensors and remote alerts (temperature, usage, maintenance alerts). These are nice-to-haves that pay off in large operations but aren’t essential for startups.

Specialized cooking: Programmable sous-vide units, high-speed ovens, or advanced fryers. These come after Tier 1 and Tier 2 are locked in.

Sizing Reality Check

Equipment dimensions matter more than you think. A combi oven that’s 1 inch too deep or 2 inches too tall can block a doorway, violate ADA reach limits, or cause a work-around nightmare that slows your entire operation.

Action: Measure your space with 2–3 inches of clearance buffer. Cross-reference equipment specs (manufacturers always list external dimensions). Test-fit critical pieces before final ordering.

5-Factor Decision Framework for Smart Equipment Selection

Once you’ve identified what type of equipment you need, how do you choose between brands and models? Price alone will bankrupt you. Use this five-factor system instead.

Factor 1: Total Cost of Ownership (TCO) Over 5 Years

Upfront price is only 30–40% of the true cost. Energy, maintenance, repairs, and replacement parts are the other 60–70%.

Example comparison (Combi Ovens):

| Cost Component | Rational iCombi Pro | Mid-Tier Competitor | 5-Year Variance |

|---|---|---|---|

| Purchase | $28,000 | $21,000 | −$7,000 |

| Energy (5 yr @ $0.14/kWh) | $4,200 | $6,800 | +$2,600 |

| Maintenance & Parts | $3,500 | $5,200 | +$1,700 |

| Downtime (labor cost) | $2,100 | $3,900 | +$1,800 |

| TOTAL 5-YEAR COST | $37,800 | $37,900 | −$100 |

The Rational appears 33% more expensive at purchase but costs virtually the same over five years due to superior energy efficiency and reliability. This is why TCO math matters.

Tool: Use our Commercial Kitchen Equipment TCO Calculator to plug in your utility rates, labor costs, and maintenance assumptions for any equipment you’re considering.

Factor 2: Energy Use

Energy efficiency directly impacts your monthly utility bill and often qualifies you for rebates.

Metrics to check:

- kBtu/hour (kilowatts per hour of operation)

- ENERGY STAR certification status (2025 standard)

- Seasonal Energy Efficiency Ratio (SEER) for refrigeration

Concrete data: AccuTemp NS-Series ventless steamers consume 35% less energy than legacy steam-jacketed models. At $0.14 per kWh (the US average), that’s approximately $412 per month in savings for a high-volume kitchen running steamers 8 hours daily.

Factor 3: Footprint Efficiency (Space per Function)

In 2026, space costs real money. Compare square footage per operational output.

Example:

- Bizerba GS series slicer: 12.5 sq ft, 22% faster portioning vs. manual

- Competitor slicer: 16.5 sq ft, standard portioning speed

- Net gain: 4 sq ft freed up for another revenue-generating station, at identical throughput

Factor 4: Compliance & Safety Certifications

Non-negotiable items:

- NSF/ANSI certification (food contact surfaces)

- ADA reach compliance (counter heights, door handles, temperature displays)

- Hood clearance (NFPA 96 ventilation standards)

- UL electrical certification (safe wiring and controls)

Missing any of these isn’t a cost savings—it’s a compliance violation waiting to happen.

Factor 5: Training, Repairability & Parts Access

Equipment that’s hard to repair or requires specialized training becomes a liability.

Key questions:

- Are replacement parts stocked locally or drop-shipped (3–5 day lead times)?

- Does the manufacturer offer training certification? (Rational iCombi systems require VEDA training; this is built into your long-term operating cost.)

- Are repair technicians available in your region?

Why it matters: Equipment downtime costs money. A combi oven that breaks down for 3 days can cost you $1,500–$3,000 in lost service hours. Vendors that support local repair networks and stock common parts are worth a premium.

Evidence-Based Brand Comparisons: Where 2026 Leaders Stand

This isn’t about declaring one brand “the best.” It’s about understanding where specific brands excel for specific problems.

Combi Ovens: Rational vs. Mid-Market Competitors

Rational iCombi Pro series:

- Strengths: Menu flexibility (100+ preset programs), energy efficiency (ENERGY STAR rated), AI sanitization tracking, modular design for easy repairs

- Weakness: Higher upfront cost ($26k–$32k depending on size)

- Best for: Operators wanting maximum menu flexibility and willing to pay a TCO-justified premium

- Not needed if: You run a highly specialized menu (e.g., pizza-only or fried chicken)

Mid-tier competitors (Hobart, Cleveland, etc.):

- Strengths: Lower purchase price ($18k–$24k), proven reliability, good availability of technicians

- Weakness: Fewer preset programs (requires manual programming), higher energy use, limited connectivity features

- Best for: Operations with defined menus and budget constraints where menu flexibility isn’t a priority

Bottom line: Choose Rational if your menu spans roasting, steaming, braising, and precision temperature work. Choose mid-tier if you have a narrow menu and want to minimize upfront spend.

Slicers: Bizerba vs. Manual + Globe Options

Bizerba GS series (auto-portion):

- Strengths: 24% smaller footprint, auto-calculating portion weights (±2% accuracy), labor reduction (22% faster than manual), NSF certified

- Weakness: Higher upfront cost ($8k–$12k), requires operator training

- Best for: High-volume prep environments (cloud kitchens, multi-location operators, charcuterie-focused menus)

- ROI timeline: ~18 months (labor savings alone)

Manual slicers or Globe models (basic):**

- Strengths: Lower cost ($3k–$5k), minimal training, familiar operation

- Weakness: Larger footprint, inconsistent portions, requires constant operator attention

- Best for: Low-volume operations or backup slicing

Recommendation: If slicing is a daily bottleneck and labor costs are rising in your area, Bizerba’s automation pays for itself. If you slice occasionally, a basic model suffices.

Holding Cabinets & Warming Equipment

AccuTemp NS-Series (connected, energy-efficient):

- Strengths: IoT monitoring (temperature alerts via phone), low energy draw, compact footprint, NSF certified

- Weakness: Requires WiFi/connectivity setup, slightly higher cost

- Best for: Cloud kitchens, multi-brand operations, or facilities with compliance auditing requirements

Traditional holding cabinets:

- Strengths: Lower cost, no tech setup required, proven reliability

- Weakness: Manual temperature monitoring, higher energy consumption

- Best for: Small kitchens or operations where temp monitoring isn’t a compliance focus

Secret Budget Killers: Planning for Maintenance, Training & Upgrades

The biggest budget killers aren’t equipment costs—they’re the hidden operational expenses that surprise you after day one.

Case Study: The Cheap Steamer That Cost 40% More

A 120-seat restaurant owner bought a $2,800 low-cost steamer to save money. Sounds smart until:

- Warranty didn’t cover $400 in repairs within year 2 (total repairs over 3 years: $1,200)

- Energy consumption was 45% higher than ENERGY STAR models, costing $85/month in excess utility bills ($3,060 over 3 years)

- No local repair technician meant 2–3 day shipping for parts, losing $200–$300 per day in prep capacity

- True 3-year cost: $2,800 + $1,200 + $3,060 + $800 (downtime) = $7,860

A $4,200 ENERGY STAR-certified steamer would have cost:

- Warranty included major repairs (add $300 for 2 minor fixes)

- Energy costs: $50/month ($1,800 over 3 years)

- Local repair technician (avg. repair turnaround: 1 day, no parts shipping)

- True 3-year cost: $4,200 + $300 + $1,800 = $6,300

The lesson: Cheap equipment has expensive true costs. Always calculate 3–5 year TCO.

Training & Certification Costs

Rational iCombi systems require VEDA (Voll-Elektro Datenverarbeitung) training for operators. This isn’t optional—it ensures your team uses 100+ preset programs correctly and maintains food safety standards.

Training cost: $400–$600 per operator, typically 4–8 hours of instruction. For a 10-person kitchen adding two combi ovens, budget $2,000–$3,000 for training across your team over the first year.

ROI: Properly trained operators on Rational systems reduce food waste by 8–12% and cook time by 15%—easily justifying the training expense.

Utility Rebate Tracking

Don’t leave rebate money on the table. ENERGY STAR equipment qualifies for:

- State utility rebates: $1,200–$1,800 per combi oven (varies by state)

- Federal tax deductions: Some equipment qualifies under Section 179 (check your accountant)

- Regional incentives: California, New York, and Texas have aggressive rebate programs

Action: When comparing equipment, ask vendors if the model qualifies for rebates in your state. Request the rebate form upfront—don’t discover eligibility 6 months after purchase.

Track rebates in our TCO Calculator, which includes state-specific rebate databases.

Preventive Maintenance Schedules

Every piece of commercial equipment requires regular maintenance. Ignoring this creates cascading failures.

Example maintenance schedule (Combi Oven):

- Weekly: Sanitize interior, check seals

- Monthly: Inspect steam generator, test temperature accuracy

- Quarterly: Professional service visit ($300–$500)

- Annually: Deep cleaning, pump/valve replacements ($800–$1,500)

Annual maintenance budget for one combi oven: $2,000–$2,500

Missing this maintenance doesn’t save money—it defers costs until something fails catastrophically. A steam generator failure on a Rational can cost $3,500+ to replace. Regular maintenance prevents this.

The 2026 Pre-Purchase Compliance & Safety Checklist

Compliance violations cost money and shut you down. Use this checklist before finalizing any equipment order.

Must-Verify Items

Hood clearance & ventilation:

- Equipment clearance from hood (NFPA 96 requires specific distances)

- Ansul system (fire suppression) installed and inspected

- Makeup air system sized correctly for cooking load

- Ductwork velocity tested (minimum 500 fpm required)

ADA accessibility:

- Work counter heights between 34–38 inches (ADA compliant)

- Door handles and controls reachable from wheelchair (max 54 inches high)

- Knee clearance under prep tables (minimum 27 inches)

- Refrigerator shelves reachable (max 54 inches)

Electrical & gas safety:

- UL certification on all equipment

- Gas line inspection by certified technician

- Circuit load calculations verified (don’t overload panels)

- GFCI outlets installed near water sources

Food safety (NSF/ANSI):

- All food contact surfaces NSF certified

- Refrigeration meets NSF/ANSI 7 (2025 standard)

- Handwash station located within 20 feet of prep area

- Three-compartment sink meets NSF standards

Propane equipment (if applicable):

- Fire code clearance limits (typically 3–10 feet from building walls, depends on jurisdiction)

- Propane tank location meets code (outdoor, ventilated)

- Shutoff valve easily accessible to operators

Local jurisdiction sign-off:

- Health department pre-opening inspection scheduled

- Fire marshal sign-off on hood/Ansul/propane

- Building permit final inspection completed

- Certificate of occupancy issued before opening

Download our full 2025-2026 Compliance Checklist with Budget Tracker to track every item and vendor required sign-offs.

Real-World ROI: How Modern Equipment Saves $18k/Year

Don’t just trust our word. Here’s how actual operators have saved money by choosing strategically.

Case Study 1: Cloud Kitchen Switching to a Bizerba Slicer

Operation: 8-location delivery-only cloud kitchen, 280 daily orders, heavy meat prep.

Before: Three manual slicing stations, each requiring one full-time operator (3 FTE @ $18/hour salary + 25% benefits = $67,500/year in labor).

After: One Bizerba GS slicer + one backup manual station, requiring 1.5 FTE ($37,500/year in labor).

Savings: $30,000/year in labor

- Equipment cost: $10,500 (Bizerba + installation)

- Payback: 4.2 months

- 5-year savings: $140,000 (accounting for operator wage growth)

Bonus: Portion consistency improved by 18%, reducing meat waste and food cost variance.

Case Study 2: FastCasual Restaurant Upgrading to ENERGY STAR Combi

Operation: 120-seat casual dining, open 6 days/week, heavy roasting + steaming.

Before: Two mid-tier combi ovens, non-ENERGY STAR, $0.18/kWh operational cost averaging $3,600/year in utilities.

After: One Rational iCombi Pro (ENERGY STAR), $0.14/kWh equivalent operational cost + utility rebate.

Savings:

- Energy: $1,200/year (33% reduction)

- Utility rebate: $1,500 (one-time)

- Reduced maintenance: $400/year (fewer breakdowns)

- Total year-one savings: $3,100

- Equipment premium over mid-tier: $6,000

- Payback: 1.9 years

- 5-year savings: $8,000 (accounting for rising energy costs)

Case Study 3: AccuTemp Holding Cabinet Reducing Food Waste

Operation: Multi-brand cloud kitchen, 6 brands sharing one kitchen, high volume of holding time for delivered orders.

Before: Standard holding cabinets with manual temperature checking—frequent food waste from temperature drift (15–20 pounds of product daily discarded due to temp variance).

After: AccuTemp NS-Series with IoT monitoring alerting staff instantly if temperature rises above 140°F.

Savings:

- Reduced food waste: 8–12 pounds daily (85% reduction in waste)

- Monthly savings: $800–$1,200 in recovered food costs

- Annual savings: $9,600–$14,400

- Equipment cost: $4,200

- Payback: 3.5 months

Bonus: Compliance documentation automated—audit readiness improved without added labor.

Next Steps: Building Your 2026 Kitchen Confidently

You now have the framework to make smart equipment decisions. Here’s how to move forward:

Step 1: Use Our Interactive Tools

Download or access our free resources:

- 2026 Equipment Compliance Checklist + Budget Tracker — Track every compliance item and vendor required signoff

- Commercial Kitchen Equipment TCO Calculator — Input your utility rates, labor costs, and maintenance assumptions to compare true costs across brands

- Equipment Comparison Matrix — Pre-loaded with Rational, Bizerba, and AccuTemp benchmarks; customize for your menu and space

Step 2: Gather Vendor Quotes Using the 5-Factor Framework

Don’t just ask for price. Request:

- Installed equipment cost

- Energy consumption spec (kBtu/hour or kW)

- ENERGY STAR certification status + local rebate amount

- Maintenance & warranty terms (parts, labor coverage)

- Training requirements and local technician availability

Compare quotes side-by-side using our matrix, not just price.

Step 3: Verify Compliance Before Finalizing Orders

Run each model against your local health department, building code, and fire marshal requirements. A 2-week compliance question is worth solving before purchase, not after delivery.

Let us plan everything for you.

If you’re opening a new kitchen, our team can walk you through your checklist, flag potential issues, and ensure your equipment plan aligns with your menu and compliance timeline. Request a planning assistance

Some Useful Resources

ENERGY STAR & Energy Efficiency

- ENERGY STAR Commercial Food Service Equipment (official database)

https://www.energystar.gov/products/commercial_food_service_equipmentenergystar - ENERGY STAR Guide for Cafés, Restaurants, and Commercial Kitchens (PDF)

https://www.energystar.gov/sites/default/files/asset/document/ES%20Restaurant%20Guide%202017-2018%20v16.pdfenergystar - ENERGY STAR Guide for Commercial Kitchens (PDF – operations and savings strategies)

https://natural-resources.canada.ca/sites/nrcan/files/energy/pdf/energystar/Commercial-Kitchen-Guide_E_acc.pdfnatural-resources.canada - ENERGY STAR Program for Commercial Kitchen Equipment (overview article)

https://www.partstown.com/cm/resource-center/guides/gd2/energy-star-program-for-commercial-kitchen-equipmentpartstown - Energy-Efficient Commercial Kitchen Equipment (practical benefits and examples)

https://www.bradyplus.com/energy-efficient-commercial-kitchen-equipmentbradyplus - Commercial ENERGY STAR Kitchen Equipment Rebates (PDF – example incentives)

https://farmersrec.com/sites/default/files/PDF_Files/2024_Rebate_Files/Commercial%20Kitchen%20Equipment%20C7.pdffarmersrec

NSF, Compliance & Certification

- NSF Food Equipment Standards (official standards portfolio)

https://www.nsf.org/nsf-standards/standards-portfolio/food-equipment-standardsnsf - NSF Food Equipment Certification (how certification works and what it covers)

https://www.nsf.org/food-beverage/commercial-food-equipment/food-equipment-certificationnsf - NSF Commercial Food Equipment Testing & Certification (services overview)

https://www.nsf.org/food-beverage/commercial-food-equipmentnsf - NSF International (organization background and history)

https://en.wikipedia.org/wiki/NSF_Internationalwikipedia

Analytics, Delivery Platforms & Cloud Kitchens

- DoorDash Merchant Analytics (official analytics tools for operators)

https://merchants.doordash.com/en-us/products/analyticsmerchants.doordash - Restaurant Analytics for Business Growth (DoorDash resource)

https://merchants.doordash.com/en-us/blog/restaurant-analyticsmerchants.doordash

SAH Kitchen Equipment Resources:

- Commercial Kitchen Equipment TCO Calculator

- Cloud Kitchen Multi-Brand Throughput Calculator

- Commercial Kitchen Order Staging & Hot-Holding Planner

- Commercial Kitchen Peak Order Wave Analyzer

When evaluating commercial kitchen equipment, how do you balance upfront cost versus long-term efficiency, especially for high-use appliances? From my experience, considering energy consumption and maintenance needs early can prevent costly downtime later. In setups like temporary or modular kitchens, having reliable refrigeration—similar to what services in Hollywood, Florida provide—can make a big difference in day-to-day operations.

Great point, Pam—you’re absolutely right. The true cost of commercial kitchen equipment goes far beyond the purchase price, especially for high-use appliances like refrigeration, cooking lines, and ware-washing.

In practice, the balance comes down to total cost of ownership: energy efficiency, build quality, serviceability, and parts availability often matter more than saving upfront. Equipment with higher efficiency ratings and proven reliability may cost more initially, but it typically pays for itself through lower utility bills, fewer breakdowns, and reduced downtime—which is critical in busy or temporary setups.

For modular or temporary kitchens, as you mentioned, dependable refrigeration is non-negotiable. Units designed for continuous operation, easy maintenance, and fast servicing can make or break daily operations, particularly in demanding environments.

That’s why in the guide I emphasize planning for long-term performance early—matching equipment specs to real usage, not just budget constraints. It’s one of the smartest ways operators can future-proof their kitchens and avoid costly surprises down the line.

Thanks for sharing your experience—it adds real-world context to an important consideration.