Reading Time: Approximately 15 minutes

Equipment procurement is where most restaurant projects either set themselves up for profitability—or lock in years of regret. We’ve worked with 200+ kitchens on equipment optimization, and the pattern is clear: operators who treat equipment purchases as strategic investments rather than line items consistently outperform those chasing the lowest sticker price.

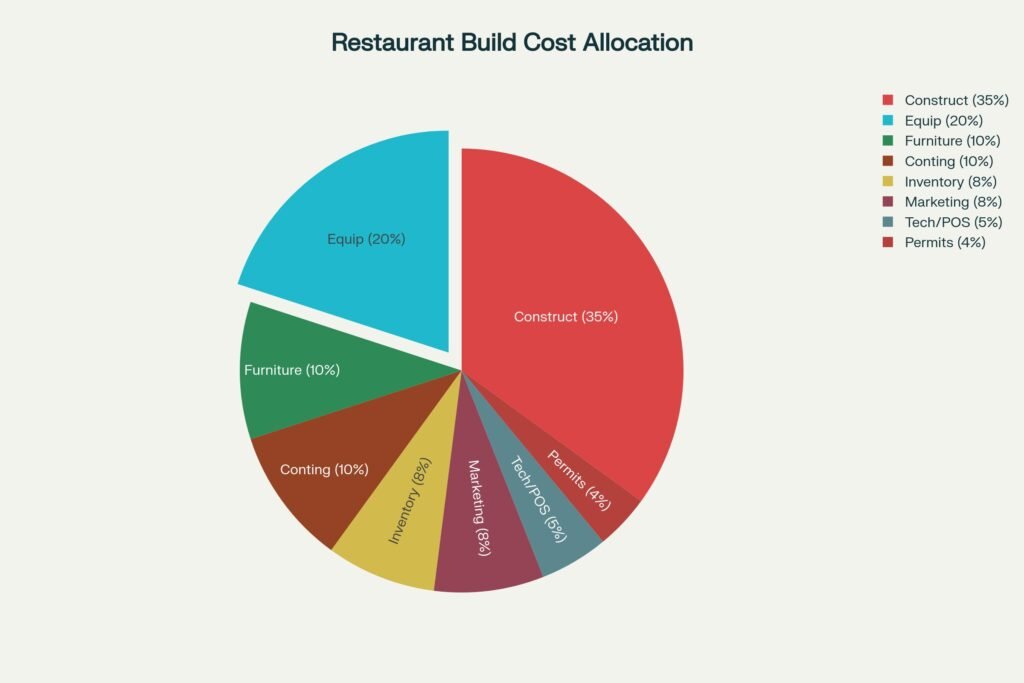

The financial stakes are significant. Equipment typically represents 15-25% of total restaurant build costs, meaning a $500,000 project allocates $75,000–$125,000 to ranges, ovens, refrigeration, and prep equipment. Yet most buyers fixate on acquisition costs while ignoring the operational expenses that compound over a decade: energy consumption, maintenance contracts, downtime losses, and premature replacement cycles.

2024 has introduced new complexity to equipment decisions. Energy costs have climbed 22% since 2021 in many markets, making efficiency specs suddenly critical to your P&L. Cloud kitchens and multi-concept operations demand flexible equipment that can pivot between cuisines without full kitchen reconfigurations. Supply chain shifts mean lead times for commercial-grade equipment now run 12-16 weeks for popular models—up from the historical 6-8 weeks.

This guide provides a systematic framework to navigate these challenges. You’ll learn how to translate your menu into precise equipment requirements, calculate true total cost of ownership using a five-component formula, verify compliance to avoid $10,000+ violations, and optimize equipment strategies specifically for delivery-only operations. Each section includes dollar-figure examples and actionable checklists that align operations teams, finance stakeholders, and compliance managers around equipment decisions that protect your investment.

Key Takeaways

- Menu Drives Equipment Needs: Conduct a thorough menu audit to align equipment purchases with your most frequently prepared dishes and peak demand volumes.

- Calculate True Costs: Evaluate equipment through a Total Cost of Ownership (TCO) lens, factoring in energy efficiency, maintenance, and potential downtime.

- Compliance is Critical: Ensure all equipment meets NSF/ANSI standards and local regulations to avoid costly fines and operational disruptions.

- Cloud Kitchen Optimization: Invest in modular, multi-functional equipment to maximize efficiency in delivery-only and multi-concept kitchens.

- Phased Procurement Plan: Use our actionable checklist to streamline your purchasing process and avoid common pitfalls.

Step 1: Translate Your Menu into Equipment Requirements

The most expensive equipment mistake isn’t buying low-quality gear—it’s buying the wrong equipment for your actual menu. A $45,000 combination oven sitting idle because your concept is 80% sautéed dishes represents capital that should have funded two high-BTU ranges instead. Menu-driven equipment planning prevents both over-buying (unused capacity draining energy) and under-buying (bottlenecks killing throughput during peak service).

Conduct a Menu Audit (With Free Template)

Start by categorizing every menu item by primary cooking method. Create a simple spreadsheet with columns for dish name, cooking method (fry/grill/bake/steam/sauté), preparation time, and portion volume. This audit reveals your true equipment priorities.

For example, if your menu analysis shows:

- 60% of dishes require sautéing or high-heat searing

- 25% need baking or roasting

- 15% use steaming or poaching

…then your equipment hierarchy should prioritize commercial ranges with at least six burners outputting 30,000+ BTU, followed by convection ovens, with steamers as a tertiary investment. We’ve seen fusion concepts waste $18,000 on oversized steamers because the equipment salesperson pushed what was in stock, when the kitchen’s actual menu used steaming for only three side dishes.

The most sophisticated operators take this further by mapping dish profitability against cooking method. If your three highest-margin items all require precision baking, suddenly that $22,000 combi oven with programmable recipe controls becomes your ROI centerpiece—not a luxury purchase.

One Asian-fusion restaurant we consulted conducted this audit and discovered a single piece of equipment could consolidate three separate cooking stations. Their menu required steaming dim sum, roasting duck, and baking desserts—traditionally handled by a steamer, convection oven, and deck oven. By investing in a combi oven with multi-stage programming, they eliminated two pieces of equipment, freed up 18 square feet of kitchen real estate (worth $4,500 annually at market rent rates), and reduced labor by eliminating the need to monitor three separate stations during rush periods.

Match Equipment Capacity to Peak Demand

Under-sizing equipment creates bottlenecks that bleed revenue during your busiest (and most profitable) service windows. Over-sizing wastes capital and inflates energy costs. The solution is straightforward math anchored to your peak-hour volume projections.

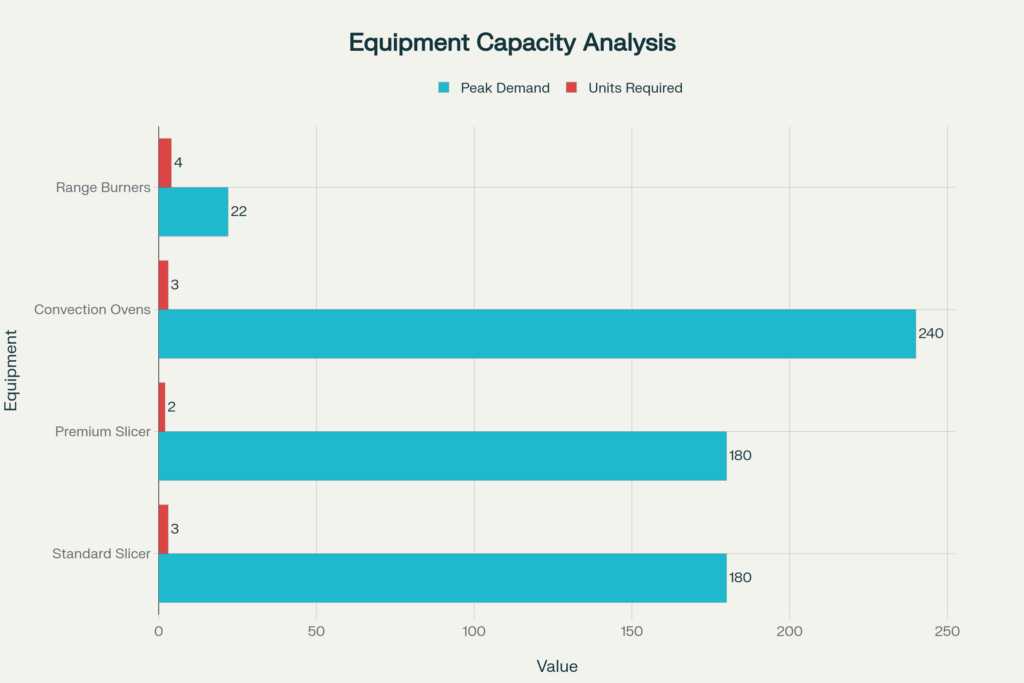

Use this formula: (Peak meals per hour) ÷ (Equipment output rate) = Units needed

Let’s walk through a practical example. Your lunch concept projects 180 orders during the 12:30–1:30 PM rush. Your signature sandwich requires slicing turkey on a commercial slicer. A standard commercial slicer processes approximately 80 portions per hour, accounting for protein loading and cleaning between batches. Your calculation: 180 ÷ 80 = 2.25, meaning you need at least two slicers to avoid creating a prep bottleneck.

But here’s where equipment quality changes the equation. A Bizerba slicer with automated feed and precision blade engineering produces 120 portions per hour with less operator fatigue. Now your math shifts: 180 ÷ 120 = 1.5, meaning a single high-throughput slicer handles your peak volume with 25% buffer capacity. The premium Bizerba model costs $3,200 versus $1,800 for a standard slicer, but you’ve eliminated the need for a second unit (and a second operator during peak). The net equipment investment is actually $1,400 less, while labor savings compound over every service shift.

Apply this same capacity-matching logic to every major equipment category:

- Ranges and cooktops: Calculate simultaneous pans needed during peak service, then multiply by 1.2 for buffer capacity

- Convection ovens: Determine sheet pans or full-size pans required per 15-minute cooking window

- Griddles: Map square inches needed for peak breakfast service (each pancake or egg requires approximately 25 square inches)

- Refrigeration: Project 7-day ingredient volume at peak weekly sales, then add 30% for inventory fluctuations and emergency stock

Workflow proximity is the final piece of menu-driven planning. Equipment that looks efficient on a specification sheet becomes an operational disaster if it creates unnecessary cross-kitchen movement patterns. Map your food flow from receiving through prep, cooking, and plating. If your menu is heavy on composed salads, your refrigerated prep tables need direct adjacency to your plating station—not separated by the cooking line.

For a detailed breakdown of combi oven programming capabilities and how to calculate exact cooking capacity for multi-menu operations, our full combi oven buying guide includes formula tables specific to baking, steaming, and combination cooking modes.

Step 2: Calculate Total Cost of Ownership (TCO) – Beyond Sticker Price

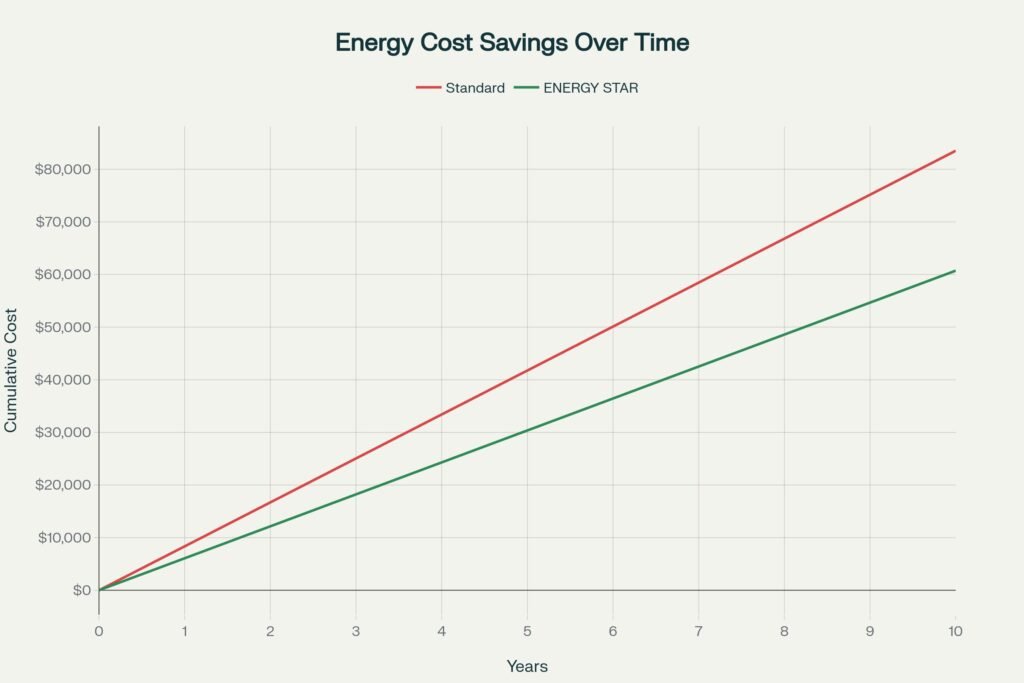

CFOs and experienced operators know that purchase price is often the smallest component of an equipment’s lifetime cost. A $15,000 combi oven that consumes 40% more energy than a $22,000 ENERGY STAR model costs $11,200 more to operate over 10 years in electricity alone—making the “cheaper” oven $4,200 more expensive in reality.

Total cost of ownership (TCO) reveals the true financial impact of equipment decisions. The comprehensive formula captures five cost components: TCO = Acquisition + (Energy × Lifespan) + Maintenance + Downtime Costs – Residual Value

The 5 Components of TCO (With Real $ Examples)

Component 1: Acquisition Costs (More Than the Price Tag)

Acquisition includes the purchase price plus delivery fees ($200–$800 depending on equipment size and origin), sales tax, installation labor, and any required facility modifications. A $12,000 range might balloon to $15,400 by the time it’s operational:

- Equipment: $12,000

- Delivery and rigging: $450

- Gas line upgrade: $1,200

- Installation labor: $600

- Sales tax (8%): $960

- Total acquisition: $15,210

The hidden costs often live in facility modifications. Installing a high-heat range might require upgrading your electrical panel ($2,200–$4,500) or enhancing ventilation to meet code ($5,000–$15,000 for hood modifications). Always request a site survey before finalizing equipment selection to surface these infrastructure expenses before purchase orders are signed.

Component 2: Energy Costs (The Silent P&L Killer)

A single piece of inefficient equipment can cost $800–$2,000 annually in wasted electricity or gas. Calculate energy costs using: (Equipment wattage ÷ 1,000) × Operating hours per day × Days per year × kWh rate = Annual energy cost

Let’s compare two identical-capacity combi ovens:

Standard combi oven:

- Power consumption: 22 kW

- Daily operation: 8 hours

- Annual usage: 22 × 8 × 365 = 64,240 kWh

- At $0.13/kWh: $8,351 per year

ENERGY STAR certified combi oven:

- Power consumption: 16 kW (27% more efficient)

- Daily operation: 8 hours

- Annual usage: 16 × 8 × 365 = 46,720 kWh

- At $0.13/kWh: $6,074 per year

Annual savings: $2,277 | 10-year savings: $22,770

The ENERGY STAR model might cost $7,000 more upfront, but it pays for itself in year 3.1 and delivers $15,770 in net savings over its service life. This is why equipment decisions require finance stakeholder involvement—operations teams may not track kWh usage, but CFOs immediately recognize a 72% ROI on the energy efficiency premium. ES Restaurant Guide (pdf)

For natural gas equipment, convert BTU ratings to therms for cost calculations: (BTU per hour × Operating hours) ÷ 100,000 = Therms consumed. Then multiply by your local gas rate (typically $0.80–$1.40 per therm).

| Equipment Type | Efficiency Premium Cost | Annual Energy Savings | Payback Period |

|---|---|---|---|

| ENERGY STAR Combi Oven | $7,000 | $2,277 | 3.1 years |

| ENERGY STAR Fryer | $1,800 | $580 | 3.1 years |

| High-Efficiency Refrigeration | $3,200 | $890 | 3.6 years |

| LED Hood Lighting | $450 | $340 | 1.3 years |

| Induction vs. Gas Range | $2,400 | $720 | 3.3 years |

Component 3: Maintenance and Service Contracts

Reliable equipment manufacturers differentiate themselves through parts availability and service network density. When a combi oven fails during Saturday dinner service, the difference between a 4-hour repair and a 3-day wait for parts represents thousands in lost revenue.

Annual maintenance costs vary dramatically by equipment quality:

Premium equipment (Rational, Alto-Shaam):

- Annual service contract: $1,200

- Average unplanned repairs: $300

- Total annual maintenance: $1,500

Economy equipment:

- Annual service contract: $800

- Average unplanned repairs: $1,200 (proprietary parts, limited availability)

- Total annual maintenance: $2,000

Factor in the service network. A Bizerba slicer has factory-trained technicians in 42 states with 24-48 hour response SLAs. An imported off-brand slicer might save $1,800 upfront but force you to wait 7-10 days for replacement parts shipped from overseas. One deli operation calculated they lost $4,200 in sales during a 9-day wait for a replacement gear assembly—wiping out the initial purchase savings and then some.

Always negotiate contracts with these provisions:

- 10-year parts availability guarantee in writing

- Maximum response time commitments (e.g., technician on-site within 24 hours)

- Loaner equipment during extended repairs for critical systems

- Annual preventive maintenance visits with detailed inspection reports

Component 4: Downtime Costs (The Hidden Revenue Drain)

| Equipment Type | Average Failure Rate/Year | Repair Time | Revenue Loss Per Incident |

|---|---|---|---|

| Economy Fryer | 2.8 failures | 6 hours | $4,800 |

| Mid-Grade Fryer | 1.2 failures | 3 hours | $2,400 |

| Premium Fryer | 0.4 failures | 2 hours | $1,600 |

| Economy Combi Oven | 3.2 failures | 8 hours | $6,400 |

| Premium Combi Oven | 0.6 failures | 3 hours | $2,400 |

Equipment failure costs extend beyond repair bills to lost sales, labor inefficiency, and menu limitations. Quantify downtime costs by estimating revenue per hour during peak periods.

If your lunch service generates $800/hour and your primary oven fails at 11 AM on a Tuesday, each hour of downtime costs you $800 in lost sales (assuming no backup capacity). A 4-hour repair window = $3,200 in missed revenue. If equipment reliability issues create three such incidents per year, downtime costs $9,600 annually—suddenly making the “expensive” equipment with a 98% uptime record look like a bargain.

Multi-concept cloud kitchens face amplified downtime risks. A single cooking equipment failure can disable three separate delivery brands simultaneously, tripling revenue loss.

Component 5: Residual Value and Equipment Lifecycle

Quality equipment retains 20-35% of purchase price after 8-10 years in service. A $20,000 combi oven from a tier-one manufacturer might resell for $5,000–$7,000 to a smaller operation when you upgrade. Economy equipment often has near-zero residual value—disposal is actually a cost, not a recovery.

Calculate expected lifespan realistically:

- Premium equipment: 12-15 years with proper maintenance

- Mid-grade equipment: 8-10 years

- Economy equipment: 5-7 years (often requiring replacement before loan terms end)

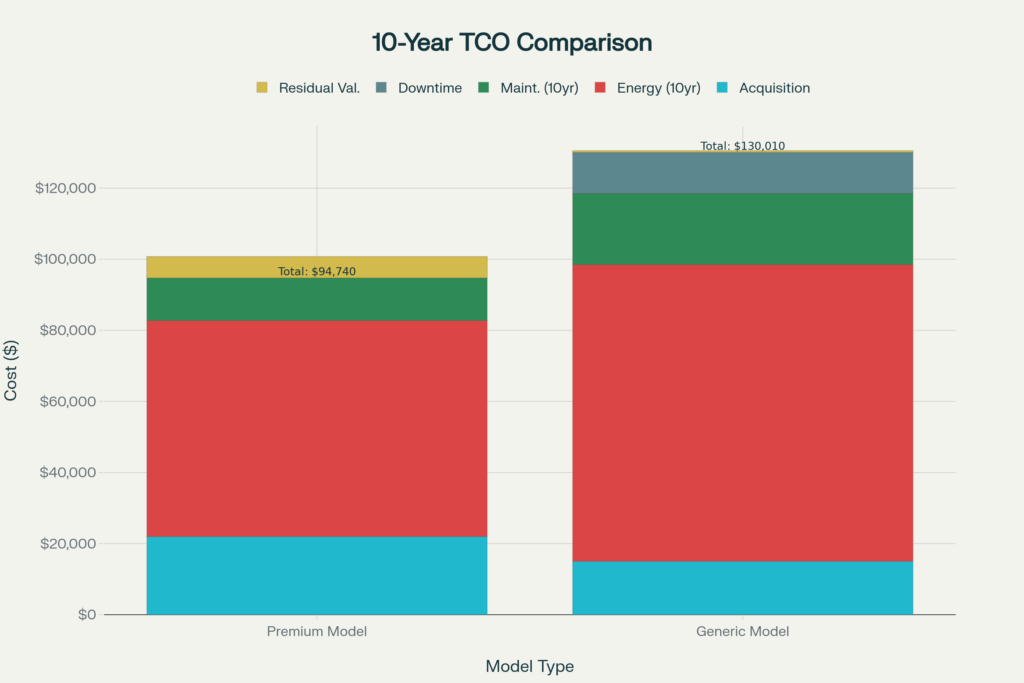

Putting It All Together: Real-World TCO Comparison

Let’s run a complete 10-year TCO analysis comparing a premium $22,000 combi oven to a generic $15,000 unit:

| Cost Component | Premium Model | Generic Model |

|---|---|---|

| Acquisition | $22,000 | $15,000 |

| Energy (10 years) | $60,740 | $83,510 |

| Maintenance (10 years) | $15,000 | $20,000 |

| Downtime costs | $3,000 | $12,000 |

| Subtotal | $100,740 | $130,510 |

| Residual value | -$6,000 | -$500 |

| Total 10-Year TCO | $94,740 | $130,010 |

The “expensive” oven actually costs $35,270 less over its lifecycle—a 37% total cost advantage.

Ready to run TCO analysis on your specific equipment list? Our interactive TCO Calculator lets you input your local utility rates, expected service hours, and equipment specifications to generate custom 10-year cost projections. Explore our free TCO Calculator to compare equipment options with the financial detail your CFO needs to approve budget allocations.

How to Negotiate TCO-Driven Vendor Contracts

Shift procurement conversations from unit price to total cost. When equipment salespeople present quotes, respond with: “Show me the 10-year operating cost breakdown, not just the purchase price.”

Request vendors provide:

- Energy consumption data with third-party ENERGY STAR validation

- Mean time between failures (MTBF) for critical components

- Average annual repair costs from existing customers in similar applications

- Parts pricing and availability guarantees

Tie payment milestones to verified performance. Instead of paying 50% upfront and 50% on delivery, structure contracts as:

- 30% on order placement

- 40% on delivery and installation

- 30% after 30-day operational validation confirming energy performance matches specifications

One regional chain saved $23,000 annually by negotiating energy performance guarantees into their hood system contract. The vendor committed that exhaust fans would consume no more than 3.2 kW during standard operation. When post-installation testing showed 3.8 kW consumption, the contract entitled the buyer to a $4,800 rebate—the calculated excess energy cost over the warranty period.

Step 3: Verify Compliance & Avoid Regulatory Pitfalls

Health inspectors can red-tag non-compliant equipment on opening day, forcing expensive emergency replacements that destroy construction timelines and blow budgets. We’ve seen operators spend $14,000 replacing “commercial-grade” equipment that lacked proper NSF certification—equipment that worked perfectly but failed regulatory requirements.

| Equipment Category | NSF-4 | NSF-7 | NSF-20 | NSF-169 | UL |

|---|---|---|---|---|---|

| Steam Tables | ✅ Required | ❌ | ❌ | ❌ | ✅ |

| Reach-In Refrigerators | ❌ | ✅ Required | ❌ | ❌ | ✅ |

| Commercial Slicers | ❌ | ❌ | ✅ Required | ❌ | ✅ |

| Combi Ovens | ❌ | ❌ | ❌ | ✅ Required | ✅ |

| Food Processors | ❌ | ❌ | ✅ Required | ❌ | ✅ |

| Hot Holding Cabinets | ✅ Required | ❌ | ❌ | ❌ | ✅ |

NSF International (formerly National Sanitation Foundation) creates the safety and sanitation standards that health departments enforce. However, not all NSF certifications are equal, and many equipment sellers exploit buyer confusion about which standards apply to specific equipment categories.

Non-Negotiable Certifications by Equipment Type

NSF/ANSI standards are numbered protocols covering specific equipment categories and safety requirements. Here’s what actually matters for your commercial kitchen equipment buying guide:

NSF/ANSI Standard 4: Commercial Cooking Rethermalization and Powered Hot Food Holding Equipment

Applies to: Steam tables, food warmers, heated cabinets, hot food merchandisers

Validates: Materials resist corrosion, surfaces are cleanable, thermostats maintain safe temperatures, electrical components are properly insulated

Red flag example: A hot holding cabinet marketing itself as “NSF-listed” but certified only under NSF-51 (food equipment materials) rather than NSF-4. NSF-51 validates materials but not the design, temperature controls, or safety features NSF-4 requires. Health inspectors in most jurisdictions will reject this equipment.

NSF/ANSI Standard 169: Special Purpose Food Equipment and Devices

Applies to: Combi ovens, cook-and-hold ovens, rotisseries, high-speed ovens

Validates: Complex cooking equipment meets heightened safety standards for multi-function devices, including proper ventilation pathways, steam venting mechanisms, and door seal integrity

Why this matters: Combi ovens combine pressurized steam and convection—creating unique safety requirements beyond standard ovens. A combi oven certified under NSF-169 confirms the manufacturer engineered proper safety interlocks preventing door openings under full steam pressure. We’ve documented steam burns from non-certified equipment lacking these safety features.

NSF/ANSI Standard 20: Commercial Bulk Milk Dispensing Equipment

Despite the name, NSF-20 extends to ANY equipment that slices, chops, or otherwise contacts ready-to-eat food during processing—including commercial slicers, food processors, and mixing equipment.

Bizerba slicers, for example, achieve NSF-20 certification through sanitary design features like removable blade guards that allow complete disassembly for cleaning and auto-shutoff functions that prevent operation when safety guards are removed. Comparable slicers lacking NSF-20 certification often have unreachable crevices where food debris accumulates, creating contamination risks that health departments cite during inspections.

UL and CSA Electrical Certification

Beyond NSF sanitation standards, all powered equipment needs UL (Underwriters Laboratories) or CSA (Canadian Standards Association) electrical safety certification. These marks confirm wiring, grounding, and electrical components meet fire safety and shock prevention standards.

Never accept “UL-recognized components” as equivalent to full UL listing. UL-recognized means individual parts (like a motor) are UL-certified, but the assembled equipment hasn’t undergone complete safety testing. Health departments and insurance carriers require full UL listing for the entire unit.

Institutional Add-On Requirements

Certain foodservice operations face additional compliance layers:

- Healthcare facilities: HACCP (Hazard Analysis Critical Control Points) compliance for patient food preparation

- Schools participating in federal meal programs: USDA equipment specifications plus Buy American requirements

- Correctional facilities: Anti-ligature designs and tamper-resistant construction

If you’re equipping institutional kitchens, verify vendors understand these specialized requirements before requesting quotes. Institutional equipment costs 15-30% more than equivalent restaurant-grade equipment due to enhanced construction and compliance validation.

Red Flags in Vendor Compliance Claims

Not all “NSF-certified” equipment actually holds valid certification. Here are the warning signs we’ve learned to identify after reviewing hundreds of equipment proposals:

Warning #1: “Stainless steel construction” marketed as equivalent to NSF certification

Stainless steel is a material specification, not a safety certification. NSF standards cover design features like:

- Rounded corners (not sharp 90° angles where debris hides)

- Smooth, non-absorbent surfaces free of imperfections

- Accessible joints for complete cleaning

- Proper drainage angles preventing water pooling

We’ve seen stainless steel prep tables with welded seams creating unreachable gaps—NSF-compliant tables use continuous smooth welds or sealed construction. Both are stainless steel; only one passes NSF standards.

Warning #2: Expired or “pending” NSF certificates

NSF certification isn’t permanent. Manufacturers must maintain ongoing compliance through periodic facility audits. Request the NSF certificate number and verification date, then validate at NSF.org’s official certification database. Enter the manufacturer name and model number to confirm current certification status.

If a vendor responds with “certification pending” or “in process,” that means the equipment is NOT certified. Period. Many operators have received “pending certification” equipment only to learn certification was denied after installation—leaving them with a $20,000 refrigeration unit that can’t legally operate.

Warning #3: Partial compliance claims

Some equipment holds NSF certification for certain configurations but not others. A reach-in refrigerator might be NSF-7 certified as manufactured, but field modifications (like adding aftermarket shelf brackets or door handles) void that certification.

Always specify: “Equipment must maintain NSF certification in as-delivered configuration, including all accessories and modifications requested in this purchase order.”

Warning #4: Certification for different equipment categories

A manufacturer might promote “NSF-certified equipment” but hold certification under irrelevant standards for the equipment you’re purchasing. Their steam tables could be NSF-4 certified (correct), but their slicers only certified under NSF-51 (materials only—insufficient for food contact equipment).

Request standard-specific certification documentation for each equipment type you’re purchasing, not blanket “we’re NSF-certified” claims.

Before finalizing any equipment purchase order, download and review the actual NSF certificate. Verify:

- Manufacturer and model number exactly match your purchase order

- Certification date is within the last 3 years

- NSF standard numbers match the standards required for that equipment type

- Certificate shows no restrictions or conditional certifications

This 5-minute validation prevents $10,000+ mistakes and protects you against installation delays when health inspectors reject non-compliant equipment.

For operators dealing with ENERGY STAR requirements alongside NSF certification, the ENERGY STAR commercial cooking equipment standards database provides searchable listings of equipment meeting both efficiency and safety certifications—streamlining vendor evaluation.

Step 4: Cloud Kitchen Equipment Strategy

Cloud kitchens, ghost kitchens, and virtual restaurant concepts operate under fundamentally different economics than dine-in establishments. Without front-of-house square footage consuming rent, these operations achieve 60-70% gross margins on delivery orders—but only if equipment decisions optimize for rapid menu pivots, maximum space efficiency, and multi-brand production from shared cooking lines.

Traditional restaurant equipment planning fails in cloud environments. A single 1,200-square-foot cloud kitchen might simultaneously produce Italian, Vietnamese, and American comfort food from the same equipment footprint. This operational model demands different equipment selection criteria than single-concept brick-and-mortar locations.

Must-Have Equipment for 2024 Cloud Kitchens

Multi-Function Cooking Equipment

Ghost kitchens can’t afford single-purpose equipment. Every square foot must generate revenue across multiple virtual brands, meaning cooking equipment needs flexible programming that switches between cuisine profiles without requiring physical reconfiguration.

Combi ovens with cloud-connected recipe libraries solve this challenge. Rather than dedicating separate ovens to Italian bakery items and Vietnamese roasted proteins, a single combi oven stores 200+ recipes accessible via touchscreen. The morning crew selects “Italian – Focaccia” to steam-bake bread using gentle humidity injection. The lunch shift switches to “Vietnamese – Char Siu Pork” using high dry heat with smoke infusion for caramelization.

Rational’s connected cooking technology takes this further by enabling remote recipe programming. Regional ghost kitchen operators with 6+ locations upload menu changes from corporate to all kitchen units simultaneously, ensuring consistency across locations without manager discretion in cook times or temperatures. This standardization prevents the quality variance that destroys cloud kitchen brands—every order of Korean BBQ short ribs receives identical 2-hour low-and-slow cooking regardless of which location prepares it.

Space-Optimizing Equipment Layouts

| Kitchen Type | Square Footage | Daily Orders | Orders per Sq Ft | Equipment Cost |

|---|---|---|---|---|

| Traditional Single-Concept | 1,200 | 180 | 0.15 | $95,000 |

| Cloud Kitchen (Multi-Brand) | 1,200 | 420 | 0.35 | $78,000 |

| Traditional Fine Dining | 2,000 | 120 | 0.06 | $145,000 |

| Ghost Kitchen Optimized | 800 | 320 | 0.40 | $62,000 |

Standard commercial kitchens allocate 5-8 square feet per meal served. Cloud kitchens must push that ratio to 12-15 meals per square foot to justify rent costs in urban markets. Space optimization starts with vertical stacking and modular equipment that adapts to fluctuating order volumes.

Self-contained ventless steamers from manufacturers like AccuTemp eliminate the need for traditional hood systems—traditionally consuming 30-40% of kitchen ceiling space and costing $8,000–$15,000 to install. Ventless technology uses contained steam generation and built-in condensation systems, allowing steamer placement anywhere with electrical access rather than restricting layout to hood coverage areas.

Modular refrigeration beats traditional walk-in coolers in cloud environments. Instead of a single 8×10 walk-in ($18,000–$24,000), deploy three reach-in refrigerators assigned to specific virtual brands ($4,500 each = $13,500 total). This distributed refrigeration model:

- Reduces cross-contamination risks between incompatible cuisines (Italian dairy near Thai fish sauce)

- Enables independent health permits for separate virtual brands

- Allows sequential build-out as you add brands rather than over-buying capacity upfront

One 300-square-foot ghost kitchen we consulted serves three distinct virtual brands:

- Italian bakery (breakfast/lunch): Combi oven + planetary mixer + reach-in refrigerator

- Vietnamese bowl concept (lunch/dinner): Induction wok range + rice cooker + undercounter refrigeration

- American comfort food (dinner): Combi oven (shared with Italian) + griddle + hot holding cabinet

By selecting dual-purpose equipment and avoiding single-function pieces, they produce 180+ orders daily from a footprint that traditional planning would accommodate maybe 60 orders.

High-Throughput Small Equipment

Cloud kitchens face compressed order windows—70% of orders often arrive within 90-minute peak periods driven by delivery platform algorithms. Equipment must support rapid parallel production rather than sequential cooking.

Induction cooktops outperform gas ranges in cloud environments due to instant temperature response and reduced ambient heat. When 40 orders for pad Thai arrive simultaneously at 6:15 PM, induction allows cooks to rapidly cycle wok stations through dishes with immediate temperature adjustment between orders. Gas burners carry thermal momentum, requiring 2-3 minutes to cool between high-heat sears and delicate sauce work—time cloud kitchens can’t afford.

Blast chillers become essential rather than optional. When you’re producing for four virtual brands, you’ll inevitably prepare components during slower periods for rapid assembly during peak delivery windows. A blast chiller drops prepared proteins, sauces, and starches from 140°F to 38°F in 90 minutes, enabling safe storage in the temperature danger zone while preserving texture better than standard refrigeration (which takes 6+ hours to cool large batches).

Thinking about launching a cloud kitchen or adding virtual brands to your existing operation? Our Cloud Kitchen Equipment Kit includes space-planning templates, equipment capacity calculators for multi-brand production, and compliance checklists specific to delivery-only operations which already helped 50+ operators launch cloud kitchens in 6–8 weeks. Get your free copy below.

3 Pitfalls Unique to Ghost Operations

Pitfall 1: Underestimating Peak Order Stacking

Traditional restaurants spread order arrival across 90-120 minute dinner services. Delivery platforms compress order arrival into 20-30 minute waves driven by customer behavior patterns and platform promotions.

We’ve seen ghost kitchens spec equipment for “100 orders during dinner” without recognizing those 100 orders might arrive as:

- 45 orders between 6:00-6:20 PM

- 30 orders between 6:45-7:05 PM

- 25 orders between 7:30-7:50 PM

That first 20-minute wave requires equipment capacity to simultaneously produce 45 meals—demanding dramatically different cooking, holding, and packaging equipment than 100 orders evenly distributed across 3 hours.

Calculate your true peak capacity requirement by analyzing delivery platform analytics. DoorDash and Uber Eats both provide order timestamp data showing when customers place orders (not when food is delivered). Identify your worst-case 20-minute order window, then multiply that order count by 3.5x to determine hourly equipment capacity needed.

Pitfall 2: Cross-Contamination in Multi-Cuisine Environments

Operating Korean BBQ, vegan bowls, and gluten-free bakery from the same kitchen creates contamination vectors that dine-in restaurants don’t face. Airborne allergens from one station drift to others, shared equipment harbors cross-contact risks, and cook staff rotation between brands spreads contamination.

Equipment selection can engineer contamination prevention:

- Color-coded cutting boards, knives, and small wares assigned permanently to specific virtual brands, stored in that brand’s dedicated refrigeration

- Separate combi oven cooking racks designated for gluten-free versus gluten-containing products, preventing airborne protein transfer during baking

- Individual ventilation zones using make-up air curtains to prevent aerosol drift from frying stations to allergen-sensitive prep areas

One cloud kitchen serving tree nut-based vegan cuisine alongside traditional American food implemented acrylic dividers between prep stations creating physical barriers preventing airborne nut protein migration. Health department testing confirmed zero contamination in finished dishes despite shared kitchen space—validating equipment-driven contamination control.

Pitfall 3: Inadequate Order Staging and Hot Holding

Ghost kitchens often fail to account for delivery driver wait times. When a driver arrives 8 minutes before food is ready, that order sits in holding—either degrading quality or occupying valuable staging space during peak production.

Traditional heat lamps don’t work for delivery orders packaged in closed containers. Invest in programmable hot holding cabinets that maintain precise 145-165°F temperatures with humidity control. Humidity-controlled holding prevents french fries from steaming inside closed containers while keeping proteins moist during 10-15 minute staging windows.

Size holding capacity to your maximum simultaneous in-progress orders, not your hourly volume. If you might have 18 orders in various completion stages during peak periods, you need holding capacity for 18 orders—even if your total hourly output is 60 orders.

Procurement Checklist & Next Steps

Equipment procurement done right follows a phased approach that aligns your operational needs, compliance requirements, and financial stakeholders before purchase orders are signed. Here’s the execution framework we’ve used with 200+ successful kitchen build-outs:

Phase 1: Requirements Definition (Weeks 1-2)

- Complete menu audit documenting cooking methods for all dishes

- Calculate peak-hour meal volumes by daypart

- Map kitchen workflow identifying equipment proximity requirements

- Define special requirements: allergen separation, multi-brand production, institutional compliance

Phase 2: Equipment Specification (Weeks 3-4)

- Match equipment capacity to peak demand using formulas from Step 1

- Identify NSF/ANSI standards required for each equipment category

- Determine energy efficiency requirements based on 10-year TCO targets

- Create prioritized equipment list with must-have vs. nice-to-have designations

Phase 3: Vendor Evaluation (Weeks 5-7)

- Request quotes from 3-5 vendors including itemized TCO components

- Validate NSF certification status for all specified equipment

- Review vendor service network coverage and response time SLAs

- Check reference accounts operating similar equipment in comparable applications

Phase 4: Financial Analysis (Weeks 8-9)

- Run complete TCO calculations comparing vendor proposals

- Model energy costs using local utility rates and projected operating hours

- Calculate total project cost including delivery, installation, and facility modifications

- Present analysis to CFO/financial stakeholders with ROI justification

Phase 5: Contract Negotiation & Installation Planning (Weeks 10-12)

- Negotiate payment milestones tied to performance validation

- Secure parts availability guarantees and maintenance contract terms

- Coordinate installation sequencing with general contractor

- Schedule pre-installation site survey to confirm utility capacity and rough-in locations

Want the complete 72-point checklist covering every validation step, specification template, and vendor evaluation scorecard? Get your Commercial Kitchen Equipment Procurement Checklist & TCO Calculator for the comprehensive planning tools that prevent the $10,000+ mistakes we’ve documented in under-planned equipment projects.

For equipment decisions, the 12-week timeline above represents ideal conditions. Current supply chains mean popular equipment models require 12-16 week lead times from order to delivery. Start your planning process at least 6 months before your target kitchen opening to accommodate specification, procurement, and delivery timelines without forcing compromised equipment decisions due to availability constraints.

Where to Go From Here

You now have the strategic framework to approach commercial kitchen equipment procurement as a long-term investment rather than a purchasing transaction. The operators who apply these TCO principles, compliance validations, and capacity-matching formulas consistently outperform competitors who chase lowest-price equipment—both in operational efficiency and financial returns.

Your next step depends on where you are in the planning process:

If you’re in early concept development, start with the menu audit outlined in Step 1. Document your cooking methods and peak volumes before looking at equipment catalogs. This foundation prevents the over-buying and under-buying mistakes that plague 60% of first-time restaurant owners.

If you’re ready to spec equipment, download our TCO Calculator and Procurement Checklist to structure your vendor evaluations around total cost, not just purchase price. The calculator includes all formulas from Step 2 pre-built for your local utility rates and operating assumptions.

If you’re specifically planning a cloud kitchen or multi-brand operation, our Cloud Kitchen Equipment Kit provides space-planning templates, capacity calculations for parallel production, and compliance strategies for multi-cuisine environments.

Ready to discuss your specific equipment needs? Our team has optimized equipment specs for fast-casual chains, hotel kitchens, institutional foodservice operations, and delivery-only concepts across 42 states. We’ll review your menu, peak volumes, budget parameters, and kitchen layout to create a specification list that balances your operational requirements with long-term TCO optimization.

Request a personalized equipment consultation or call us to connect with a kitchen equipment specialist who understands your specific operational concept.

The $50,000–$150,000 you invest in commercial kitchen equipment will influence your food costs, labor efficiency, and maintenance expenses for the next 10-15 years. Make those decisions with the strategic rigor they deserve—your P&L will reflect the difference every single month.

Some Useful Resources

ENERGY STAR & Energy Efficiency

- ENERGY STAR Commercial Food Service Equipment (official database)

https://www.energystar.gov/products/commercial_food_service_equipmentenergystar - ENERGY STAR Guide for Cafés, Restaurants, and Commercial Kitchens (PDF)

https://www.energystar.gov/sites/default/files/asset/document/ES%20Restaurant%20Guide%202017-2018%20v16.pdfenergystar - ENERGY STAR Guide for Commercial Kitchens (PDF – operations and savings strategies)

https://natural-resources.canada.ca/sites/nrcan/files/energy/pdf/energystar/Commercial-Kitchen-Guide_E_acc.pdfnatural-resources.canada - ENERGY STAR Program for Commercial Kitchen Equipment (overview article)

https://www.partstown.com/cm/resource-center/guides/gd2/energy-star-program-for-commercial-kitchen-equipmentpartstown - Energy-Efficient Commercial Kitchen Equipment (practical benefits and examples)

https://www.bradyplus.com/energy-efficient-commercial-kitchen-equipmentbradyplus - Commercial ENERGY STAR Kitchen Equipment Rebates (PDF – example incentives)

https://farmersrec.com/sites/default/files/PDF_Files/2024_Rebate_Files/Commercial%20Kitchen%20Equipment%20C7.pdffarmersrec

NSF, Compliance & Certification

- NSF Food Equipment Standards (official standards portfolio)

https://www.nsf.org/nsf-standards/standards-portfolio/food-equipment-standardsnsf - NSF Food Equipment Certification (how certification works and what it covers)

https://www.nsf.org/food-beverage/commercial-food-equipment/food-equipment-certificationnsf - NSF Commercial Food Equipment Testing & Certification (services overview)

https://www.nsf.org/food-beverage/commercial-food-equipmentnsf - NSF International (organization background and history)

https://en.wikipedia.org/wiki/NSF_Internationalwikipedia

Analytics, Delivery Platforms & Cloud Kitchens

- DoorDash Merchant Analytics (official analytics tools for operators)

https://merchants.doordash.com/en-us/products/analyticsmerchants.doordash - Restaurant Analytics for Business Growth (DoorDash resource)

https://merchants.doordash.com/en-us/blog/restaurant-analyticsmerchants.doordash

SAH Kitchen Equipment Resources:

- Commercial Kitchen Equipment TCO Calculator

- Cloud Kitchen Multi-Brand Throughput Calculator

- Commercial Kitchen Order Staging & Hot-Holding Planner

- Commercial Kitchen Peak Order Wave Analyzer

Must Also Read

- The Culinary Leader’s Rational Combi Oven Buying Guide: Maximize ROI & Consistency

- Bizerba Commercial Scales Buying Guide: Choose the Right Model for Compliance & Efficiency

- Commercial Steam Kettle Buying Guide: ROI-Focused Selection for High-Volume Kitchens

- Essential Cloud Kitchen Equipment: Maximizing Output in Under 500 Sq Ft (2025-2026 Guide)